What makes modern structures lightweight yet durable enough to support industrial equipment, sleek store displays, and energy-efficient lighting systems? The answer often lies in an unassuming but critical component: aluminum channels. These U-shaped or C-shaped extruded profiles serve as the invisible framework for countless applications, combining structural integrity with practical versatility.

Aluminum channels are created through an extrusion process where heated aluminum alloy is forced through a die to create continuous lengths of standardized shapes. Unlike heavier steel alternatives, these channels offer:

You'll find aluminum channel uses spanning three key sectors:

The benefits of aluminum channel become particularly evident in moisture-prone environments. Unlike steel that requires galvanizing to prevent rust, aluminum naturally resists corrosion – a critical advantage for outdoor applications like truck bed framing or marine facility structures. This adaptability extends to thermal performance too; aluminum channels in LED systems can dissipate heat 35% more efficiently than plastic alternatives.

Modern manufacturers have pushed the boundaries of aluminum channel design, creating specialized profiles that integrate mounting slots, thermal breaks, and even decorative finishes. This evolution positions aluminum channels as the smart choice for projects balancing structural demands with weight constraints and aesthetic requirements.

Why are engineers increasingly choosing aluminum channels over traditional steel or wood components? The answer lies in three game-changing benefits: unmatched strength-to-weight ratios, inherent corrosion resistance, and adaptability across industries. Let’s break down what makes these extruded profiles a superior choice for modern projects.

Aluminum channels achieve the Goldilocks principle of structural materials – strong enough to support heavy loads yet light enough for easy handling. Pound for pound, aluminum provides 65% of steel’s strength at just 45% of its weight , making them ideal for applications like aerial work platforms and modular building systems. This weight reduction translates to:

Unlike steel that rusts or wood that warps, aluminum channels form a self-repairing oxide layer when exposed to moisture. This natural barrier makes them perfect for:

In salt spray tests comparing aluminum channel vs steel counterparts, aluminum showed 90% less material degradation after 5 years of simulated exposure.

The true test of any material lies in real-world performance. Aluminum channels excel in diverse scenarios:

As we’ll explore next, these advantages stem from precise engineering of aluminum channel profiles – a topic that reveals even more customization opportunities for specialized projects.

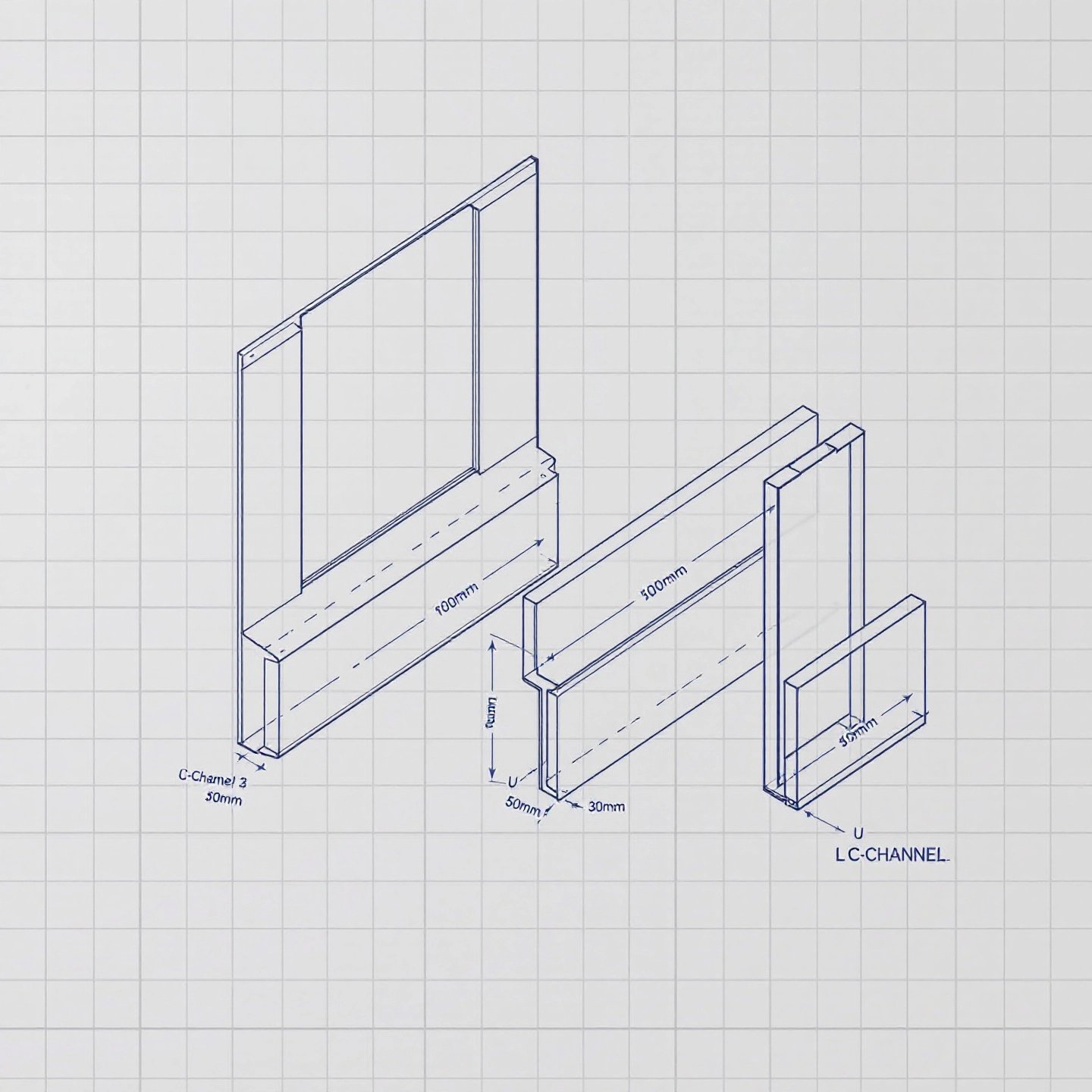

Ever wondered how engineers select the right aluminum channel shape for specific applications? The secret lies in understanding standard profiles – let's break down the three most common types with precision.

| Profile | Thickness Range | Load Capacity | Common Uses |

|---|---|---|---|

| C-Channel | 1/8"-3/4" (3.2-19mm)* |

Medium-High (Up to 73 ksi yield) |

Structural framing Equipment racks |

| U-Channel | 0.25-6mm | Low-Medium (15-40 ksi yield) |

Edge protection LED housing |

| L-Channel | 1"-12" legs (25-305mm) |

Low (Up to 31 ksi yield) |

Corner reinforcement Trim finishing |

*Per ASTM B221 specifications for 6061-T6 alloy

Standard C-channels range from compact 2" models to heavy-duty 15" profiles, with web thicknesses progressing from aircraft-thin 0.130" (3.3mm) to robust 0.716" (18.2mm). The AISC 360-22 standard calculates their impressive load capacities:

U-channels excel where precision meets protection. Their 0.25-6mm walls (about 0.01"-0.24") make them ideal for:

Custom Profile Note: When standard sizes don't fit, manufacturers like Sunmay Aluminum extrude custom channels up to 700mm wide with 0.25mm thin-wall precision – perfect for specialized architectural or aerospace applications requiring tight tolerances.

While L-channels serve basic corner reinforcement, C and U profiles offer surprising versatility. A 6" U-channel can moonlight as both a bookshelf rail and machine guard, proving aluminum's adaptability. Next, we'll explore how architects push these profiles further with specialized channel designs.

What do modern building facades and energy-efficient interiors have in common? Both rely on specialized aluminum channels that go beyond basic structural support to solve specific design challenges. Let’s explore five advanced profiles transforming contemporary architecture.

Widely used in commercial construction, hat channels create level surfaces for drywall and acoustic panels. Their distinctive flanged design ( typically 2-3/4″ x 7/8″ ) provides:

F-channels feature a unique lip design that securely holds glass panels in curtain walls and storefronts. Key installation considerations include:

Pro Tip: When specifying Z-channels for thermal applications, pair them with polyamide strips to achieve thermal conductivity values below 0.5 W/m·K .

These specialized profiles demonstrate aluminum’s adaptability in solving complex architectural challenges while maintaining sleek aesthetics. As we’ll explore next, this thermal management capability becomes crucial when integrating channels with modern LED lighting systems.

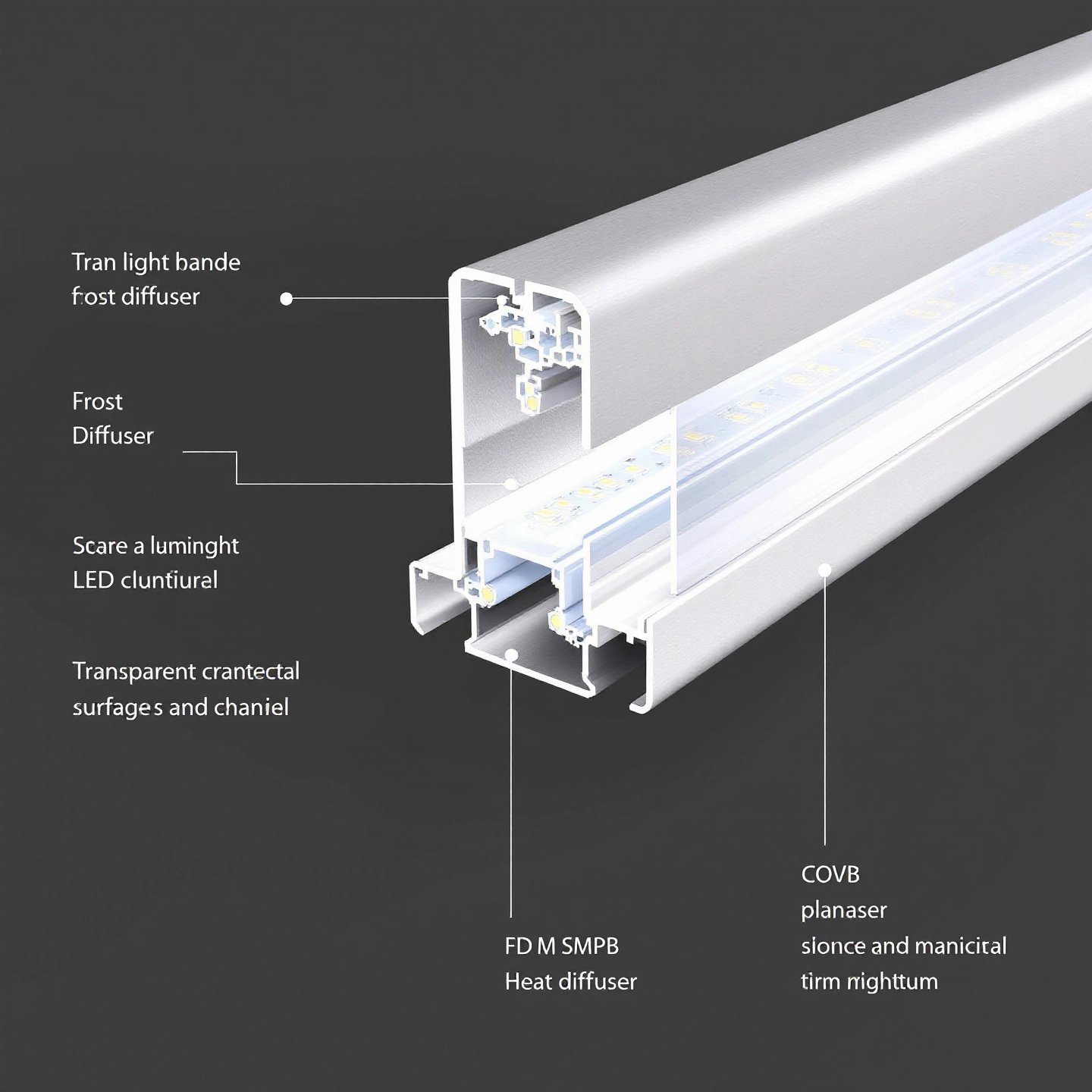

Building on aluminum's thermal management capabilities from architectural applications, let's explore how LED strip aluminum channel systems solve two critical lighting challenges: heat dissipation and aesthetic integration. Aluminum channels transform basic LED strips into professional-grade lighting solutions through smart engineering.

Aluminum channels act as natural heat sinks, reducing LED operating temperatures by up to 30% compared to bare installations . This thermal regulation extends LED lifespan by preventing premature lumen depreciation – a key factor in commercial settings where lighting runs 12+ hours daily.

| Type | Installation Depth | Best For | IP Rating* |

|---|---|---|---|

| Surface-Mount | 0mm (wall-mounted) | Retrofit projects, under-cabinets | IP54-IP65 |

| Recessed | 10-25mm | New construction, ceilings | IP20-IP44 |

* IP rating guide for moisture protection levels

By combining these factors, you create LED installations that balance performance with durability. A well-designed aluminum channel system not only enhances light quality but also protects your lighting investment from environmental stressors – whether it's bathroom humidity or outdoor weather exposure.

How do factories move tons of materials daily while maintaining worker safety? The answer lies in engineered aluminum channel systems designed for industrial rigor. From automated production lines to aircraft assembly, these high-strength profiles deliver unmatched performance.

| Alloy | Temper | Yield Strength | Best For |

|---|---|---|---|

| 6061 | T6 | 40 ksi | Structural frames |

| 6063 | T5 | 31 ksi | Architectural trim |

| 7075 | T6 | 73 ksi | Aerospace components |

*Data sourced from ASM Material Data Sheets

Expert Insight: For critical aerospace applications, 7075-T6 channels offer 73 ksi yield strength – comparable to many steels but with 3x better corrosion resistance. Manufacturers like Sunmay Aluminum specialize in extruding these high-performance alloys with ±0.1mm dimensional tolerances.

Selecting the right alloy requires balancing strength needs with environmental factors – a decision matrix we'll explore next when choosing channels for specific applications.

How do you ensure your aluminum channel performs flawlessly for decades? The secret lies in matching five essential specifications to your project's unique demands. Let's break down these decision-making factors with real-world examples.

| Treatment | Thickness | Best For |

|---|---|---|

| Anodized | 5-25μm | Chemical plants, coastal areas |

| Powder-Coated | 60-120μm | Retail displays, architectural features |

Pro Tip: For coastal bridge projects, combine marine-grade aluminum channels (5083 alloy) with Class I anodizing per MIL-A-8625 – this pairing withstands salt spray 3x longer than standard coatings.

By systematically evaluating these five factors against your project parameters, you'll select channels that optimize performance while avoiding costly over-engineering. Next, we'll explore how proper maintenance extends the life of your chosen aluminum channels.

How do you keep aluminum channels performing like new while unlocking their full potential? The answer lies in two crucial practices: proper maintenance for longevity and strategic customization for specialized applications. Let's break down proven techniques for both.

Different finishes require tailored cleaning approaches to preserve their integrity:

For stubborn contaminants:

Pro Tip: For marine environments, clean channels quarterly using ASTM G85-compliant methods to prevent salt accumulation.

When standard profiles fall short, manufacturers like Sunmay Aluminum deliver precision-crafted solutions through advanced extrusion capabilities:

| Capability | Specification | Application Example |

|---|---|---|

| Section Size | Up to 700mm | Oversized solar panel framing |

| Wall Thickness | 0.25mm precision | Aerospace heat exchangers |

| Certification | TS16949/IATF 16949 | Automotive structural components |

Sunmay's custom extrusion services enable:

Case Study: A recent project required 12-meter continuous extrusions with 0.3mm wall consistency – achieved through Sunmay's proprietary die cooling technology and EN 12020-12022 compliance .

By combining proper maintenance with tailored engineering, aluminum channels deliver decades of reliable service across industries. Next, we'll examine how global quality standards ensure consistent performance worldwide.

How do global manufacturers ensure their aluminum channels meet diverse international requirements? The answer lies in rigorous adherence to two pivotal standards: Europe’s EN 755 and America’s ASTM B221. Let’s decode these specifications and their real-world implications for quality assurance.

| Standard | Scope | Key Requirements | Testing Protocols |

|---|---|---|---|

| EN 755-2 (European) |

Extruded rods/bars/tubes |

|

Third-party verification mandated for CE marking |

| ASTM B221 (American) |

Extruded bars/rods/shapes |

|

Supplier self-certification accepted |

*Data referenced from International Aluminum Extrusion Manual

Leading suppliers like Sunmay Aluminum bridge these standards through:

Case in Point: Sunmay’s TS16949-certified processes achieve ±0.1mm dimensional accuracy – exceeding both EN 755’s ±0.5% and ASTM B221’s 0.125”/ft requirements.

Third-party testing protocols ensure impartial validation:

This multi-layered approach guarantees that whether you specify ASTM B221 aluminum channels for a Chicago high-rise or EN 12020 compliant channels for a Berlin hospital, you receive consistent, certified quality. As we conclude, discover how these global standards align with sustainable construction trends and partner selection strategies.

As global quality standards evolve to meet sustainability targets, aluminum channels emerge as the smart choice for eco-conscious projects. With 75% of all aluminum ever produced still in use today , these profiles form the backbone of circular construction – but their full potential unlocks only with expert partners.

Sunmay Aluminum combines sustainable material science with precision engineering to deliver:

These capabilities empower architects and engineers to create structures that achieve 59% lower carbon footprints compared to 1990s benchmarks while maintaining structural integrity. From earthquake-resistant frameworks to zero-waste manufacturing lines, aluminum channels prove that sustainable design doesn't compromise performance.

Ready to elevate your next project? Explore Sunmay's channel solutions catalog to discover custom extrusions tailored to your technical and environmental requirements. With 700mm section capabilities and ±0.05mm tolerances, your most ambitious designs become achievable realities.

Aluminum channels serve as structural components in construction (window framing, curtain walls), industrial systems (conveyor rails, machinery guards), and LED lighting (heat-dissipating housings). Their corrosion resistance makes them ideal for marine applications and outdoor projects like truck bed framing.

While aluminum channels weigh 45% less than steel, high-grade alloys like 7075-T6 achieve 73 ksi yield strength - comparable to many steels. Industrial-grade 6061-T6 channels support up to 1,850 lbs/ft loads, with enhanced corrosion resistance for long-term durability.

6061-T6 aluminum channels combine 40 ksi yield strength with excellent machinability, making them ideal for structural applications. Sunmay Aluminum's TS16949-certified extrusions meet ASTM B221 standards, offering ±0.1mm tolerances for precision engineering projects.

Clean anodized channels with pH-neutral solutions and soft brushes. For powder-coated surfaces, use mild detergents (<2% concentration) and <1,500 psi pressure washing. Sunmay recommends quarterly salt removal for marine applications using ASTM G85-compliant methods.

Yes, manufacturers like Sunmay Aluminum extrude custom profiles up to 700mm wide with 0.25mm thin-wall precision. Their EN 12020-compliant services support specialized needs including integrated cooling channels and multi-chamber thermal breaks.

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on