What transforms a dull aluminum surface into a radiant showpiece? The answer lies in effective aluminum polishing – a process that does more than create visual appeal. Beyond its reflective finish, aluminum polish plays a critical role in preserving metal integrity by combating corrosion and oxidation. From vintage car restorations to marine equipment maintenance, this essential process bridges industrial durability with aesthetic excellence.

Modern applications demand both form and function from aluminum components. Consider these key benefits:

Industries relying on polished aluminum span far beyond typical expectations. Automotive enthusiasts use specialized compounds to maintain show-quality wheels, while aerospace engineers depend on precision polishing for aerodynamic components. In domestic settings, polished aluminum range hoods and furniture accents combine easy maintenance with modern elegance.

Through this comprehensive resource, you'll discover:

Whether restoring antique aluminum signage or maintaining commercial kitchen equipment, understanding proper polishing protocols ensures surfaces remain structurally sound while projecting professional-grade aesthetics. The following chapters break down this complex process into actionable, industry-approved steps.

Why does your neighbor's aluminum boat gleam like new while yours shows cloudy patches? The answer lies in understanding how different aluminum alloys interact with polishing techniques. Let's break down the science behind achieving that flawless finish.

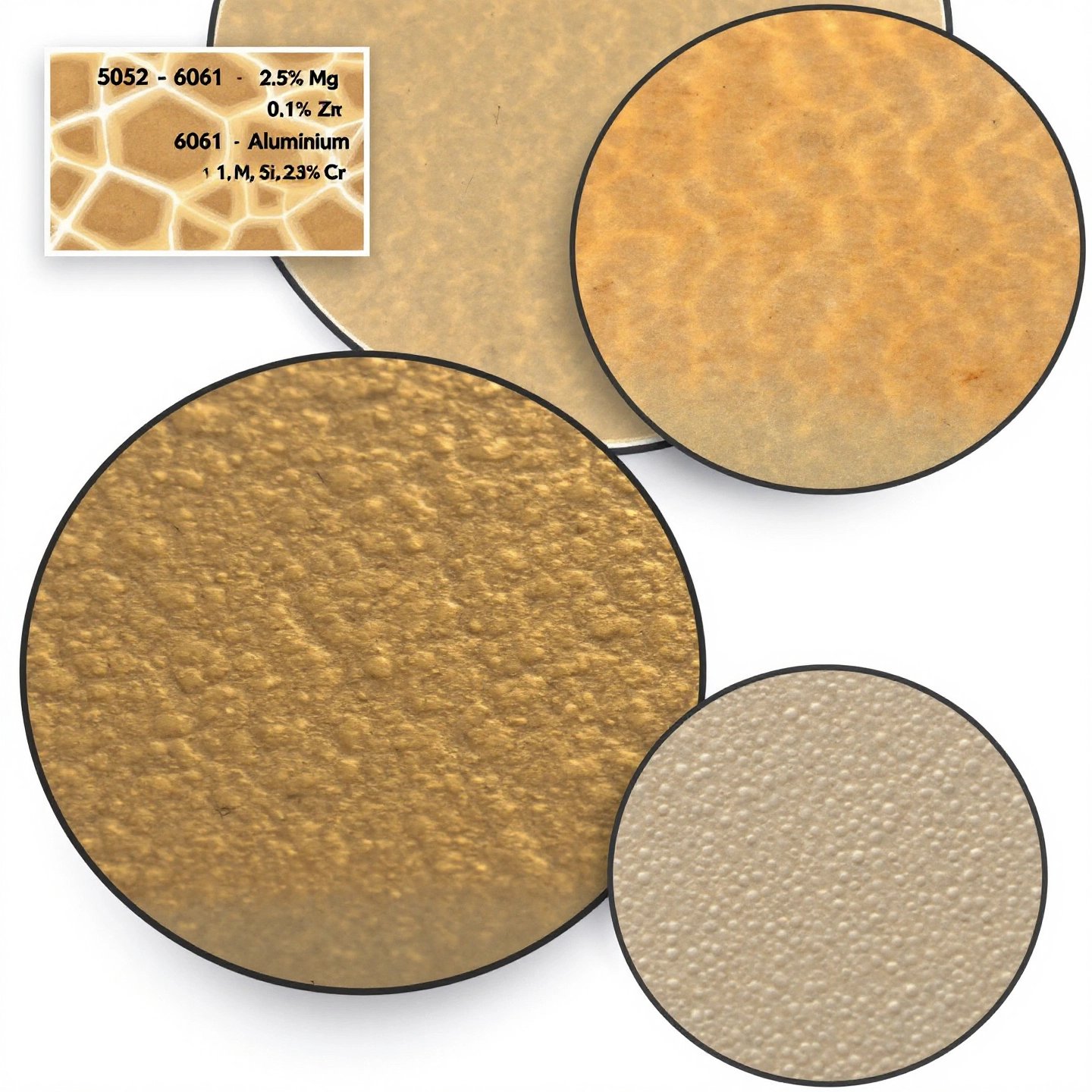

Not all aluminum responds equally to polishing. Three common alloys demonstrate distinct behaviors:

| Alloy | Key Traits | Polishing Approach |

|---|---|---|

| 5052 | High corrosion resistance (Common in marine applications) |

• Mechanical polishing with rotary buffers • Avoid aggressive abrasives |

| 6061 | Structural strength (Used in automotive frames) |

• Multi-stage sanding (400-1500 grit) • Requires oxidation removal first |

| 6063 | Smooth surface finish (Popular for architectural trim) |

• Minimal sanding needed • Responds well to paste compounds |

As highlighted in McCoy's Truck Detailing research, 6061 aluminum demands extra attention to oxidation before polishing – a critical step many DIYers overlook.

All aluminum forms a protective oxide layer, but environmental factors can breach this defense:

A recent study showed unpolished marine-grade aluminum develops visible pitting within 90 days of saltwater exposure. Proper polishing removes existing oxidation while creating a smoother surface that resists new corrosion.

Consider these real-world scenarios:

Case 1: Pitted 6061 Truck Wheels

• Before: Deep oxidation pockets from road salt

• Solution: 220-grit sanding → oxidation neutralizer → diamond-cut compound

• Result: 80% surface restoration with mirror reflectivity

Case 2: Scratched 6063 Window Trim

• Before: Hairline scratches from improper cleaning

• Solution: Non-woven abrasive pad → cerium oxide polish

• Result: Scratch-free surface with factory-like finish

Understanding these material nuances helps avoid costly mistakes. Next, we'll explore how to set up your workspace with the right tools to tackle these challenges effectively.

What separates amateur results from professional-grade finishes? It starts with proper preparation. A well-organized workspace with the right tools ensures efficient polishing while minimizing safety risks. Let's break down the essentials for setting up your aluminum polishing station.

Based on industry standards, every aluminum polishing setup requires:

For beginners, a basic rotary buffer ($90-$150 range) paired with a 3-stage compound system typically yields satisfactory results. Professionals often invest in variable-speed grinders ($200+) for better control over intricate surfaces.

Proper surface degreasing prevents contaminants from ruining your polish. Compare popular options:

| Agent | Best For | Precautions |

|---|---|---|

| Isopropyl Alcohol (70%) | Light oxidation Budget-friendly prep |

• Flammable • Requires ventilation |

| Specialized Degreasers | Heavy grease/oil Industrial applications |

• pH-neutral formulas preferred • Wear rubber gloves |

| Aluminum Brighteners | Restoring dull surfaces Pre-polish treatment |

• Acidic formulas • Rinse thoroughly |

As noted in OSHA guidelines, always consult Safety Data Sheets (SDS) before using chemical cleaners.

Protect yourself with these critical measures:

Pro Tip: Designate separate cloths for different tasks – never mix metal dust removal rags with final polishing cloths. Now that your workspace is primed, let's dive into the step-by-step polishing process that transforms weathered aluminum into mirror-like perfection.

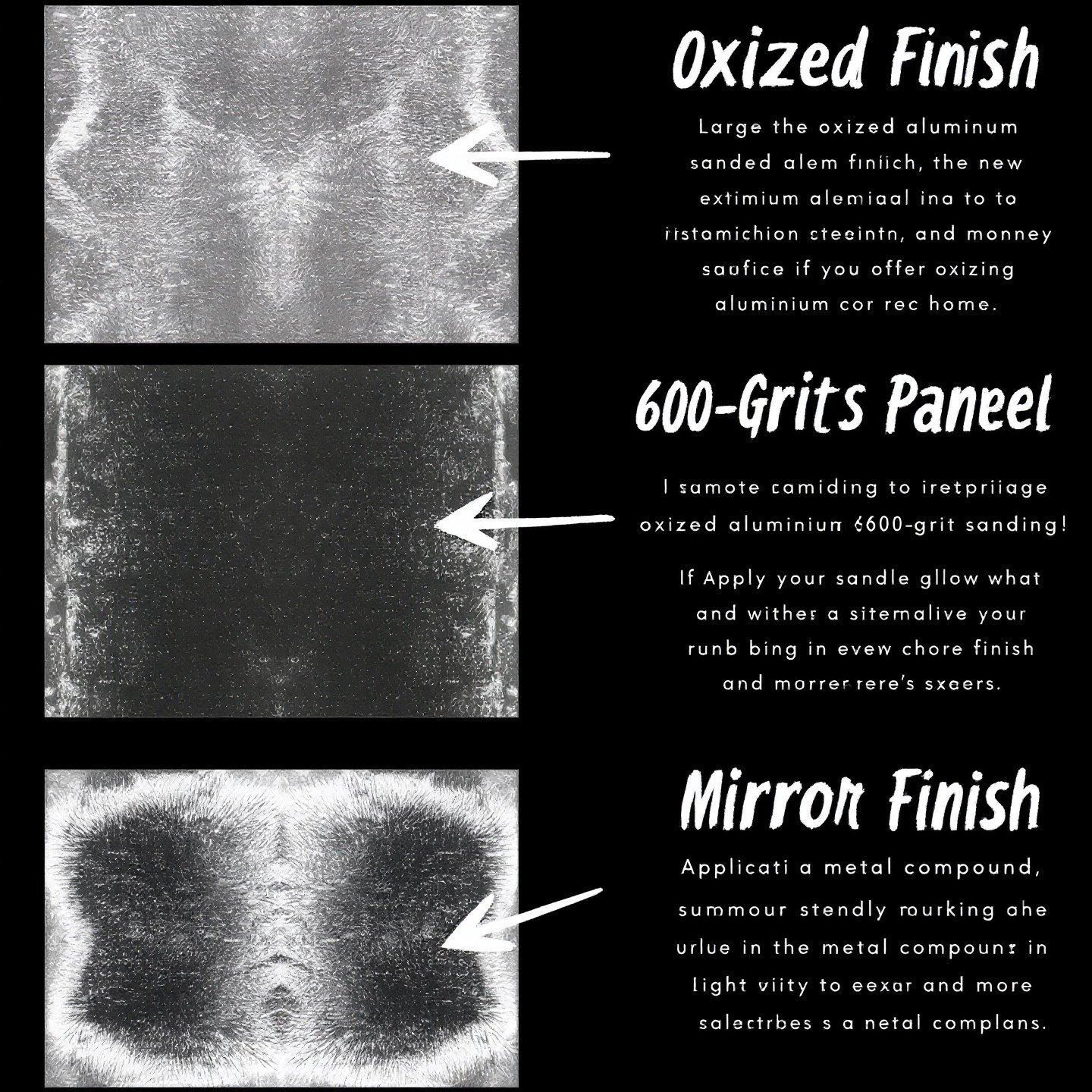

Want that showroom-quality finish on your aluminum surfaces? Achieving a flawless mirror shine requires methodical progression through five critical stages. Let's break down the professional process used by detailers and metal fabricators worldwide.

Sunmay Aluminum's T6-tempered profiles simplify the process through:

| Feature | Polishing Benefit |

|---|---|

| RA <0.8μm surface finish | Reduces required sanding stages by 40% |

| Precision extrusion tolerances | Minimizes uneven compound distribution |

| Anodized ready surfaces | Accepts sealants 3x faster than standard alloys |

As demonstrated in Sunmay's surface treatments, properly engineered aluminum requires less aggressive polishing while delivering superior reflectivity. This streamlined approach saves 2-3 hours per square meter compared to standard alloys.

Mastering this sequence transforms even weathered aluminum into mirror surfaces that rival commercial chrome plating. Next, we'll explore specialized techniques for maintaining this brilliance on high-wear components like wheels and rims.

Why do polished aluminum wheels lose their luster faster than other components? The answer lies in brake dust – a corrosive cocktail of metal particles and carbon residue that demands specialized removal techniques. Let’s explore professional methods to maintain showroom-quality wheels and rims.

Effective brake dust removal requires a 3-stage approach:

For motorcycle rims with intricate designs, use detailing swabs to clean spoke junctions and valve stems. Always wear nitrile gloves and eye protection when handling acidic cleaners.

| Type | Best For | Durability |

|---|---|---|

| Spray Polishes | Quick touch-ups Light oxidation |

2-3 weeks |

| Paste Compounds | Deep restoration Scratch removal |

6-8 weeks |

While sprays offer convenience, paste polishes provide longer-lasting protection – particularly beneficial for daily-driven vehicles. For vintage motorcycle rims, use non-abrasive creams to preserve original machining marks.

High-quality wheel sealants act as force fields against contaminants. Top performers share these traits:

Advanced synthetic formulas now offer 6-9 month protection, outperforming traditional carnauba waxes. Apply sealants to completely dry wheels using foam applicators, focusing on barrel surfaces and lug nut recesses.

Pro Tip: When polishing aluminum wheels, always check manufacturer guidelines – some clear-coated designs require specific pH-neutral products to avoid finish degradation. Combine these techniques with the sanding sequences from Chapter 4 for heavily oxidized surfaces, and your wheels will maintain their mirror-like brilliance through seasons of road abuse.

Ever wondered if household items could rival commercial aluminum polishes? Many DIY enthusiasts have discovered surprising results using common pantry staples. Let’s examine when homemade solutions shine and when professional-grade products prove worth the investment.

Pro Tip: Test homemade cleaners on inconspicuous areas first. Avoid mixing vinegar and baking soda – they neutralize each other’s cleaning power.

| Solution | Cost/Use | Effort Level | Best For | Limitations |

|---|---|---|---|---|

| Vinegar Mix | $0.10 | Moderate | Light oxidation | Requires multiple applications |

| Baking Soda Paste | $0.15 | High | Stubborn stains | Can cloud anodized surfaces |

| Commercial Polish | $0.75 | Low | Heavy restoration | Higher upfront cost |

Commercial aluminum polishes outperform DIY methods in three key scenarios:

Never use these on anodized surfaces:

As CRC Surface Technologies advises, use pH-neutral cleaners and soft cloths to preserve anodized coatings. Damaging this layer exposes raw aluminum to corrosion.

While polishing aluminum with toothpaste works for minor scratches on untreated surfaces, it’s less effective than specialized compounds. For consistent results on quality materials like Sunmay’s anodized profiles, stick to manufacturer-recommended cleaners.

Up next: Professional-grade polishing kits that combine these principles with industrial-strength results.

Overwhelmed by polishing kit options? The right tools can mean the difference between frustration and flawless results. Let’s dissect three professional-grade solutions that cater to different skill levels and project requirements.

| Kit | Price | Included Components | Best For |

|---|---|---|---|

| Renegade Aluminum Mini Kit | $106 | • 8" buffing wheels (2 types) • Tripoli & green rouge compounds • Microfiber towels & pads • Safety flanges |

Marine/auto restoration (Source) |

| Mothers Mag Wheel Polish | $18 | • 10oz polish compound • Foam applicator • Microfiber buffing cloth |

Quick wheel touch-ups |

| Zephyr Pro 40 Kit | $245 | • 40-piece wheel/pad set • 4-stage compounds • Mandrels & backplates |

Commercial metal shops |

Understanding abrasive levels is crucial for comparing metal polish compounds:

Beginners should prioritize kits with multiple compound grades like Renegade’s system – ideal for best aluminum polishing kit for beginners seeking professional results without equipment overload.

Sunmay Aluminum’s precision-engineered T6 profiles revolutionize polishing efficiency:

As detailed in Sunmay’s technical specifications, their T6 tempering process creates surfaces with RA ≤0.8μm – nearly 50% smoother than industry averages. This allows users to skip aggressive cutting stages, preserving more base material while achieving superior reflectivity.

Whether restoring vintage motorcycle parts or maintaining architectural trim, these kits provide tailored solutions for every aluminum challenge. Next, we’ll explore how to maximize your chosen compounds’ potential with top-rated polish brands.

What separates a good aluminum polish from a great one? With countless options promising mirror finishes, we’ve analyzed performance data and user reviews to identify the top contenders. Here’s how leading brands stack up in real-world applications.

| Brand | Rating | Viscosity | Best For | Durability |

|---|---|---|---|---|

| Mothers Mag | 4.7★ | Medium paste | Beginners & wheels | 6-8 weeks |

| Busch Super Shine | 4.5★ | Thick gel | Heavy oxidation | 10+ weeks |

| Zephyr Liquid | 4.6★ | Low viscosity | Large surfaces | 4-6 weeks |

| Blue Magic | 4.4★ | Cream | Multi-metal use | 5-7 weeks |

| Flitz Multi-Purpose | 4.8★ | Liquid | Delicate finishes | 8-10 weeks |

As Sheen Genie’s research confirms, viscosity directly impacts polish performance:

For components exposed to extreme heat:

Based on 850+ verified reviews:

While Blue Magic’s ammonia smell draws complaints, its versatility across metals makes it a workshop favorite. For those maintaining Sunmay’s T6-tempered aluminum, Busch’s gel provides ideal aggression without compromising the hardened surface.

Armed with this comparison, you’re ready to select the perfect polish. Up next: Proven strategies to maintain your newly restored shine through seasons of use.

How often should you tend to polished aluminum to keep its mirror-like brilliance? The secret lies in a strategic care routine that balances frequency with the right protective measures. Let’s break down a professional maintenance system that prevents corrosion while minimizing effort.

| Interval | Tasks | Tools Needed |

|---|---|---|

| Every 30 Days | • Wash with pH-neutral soap • Inspect for water spots • Quick-dry with microfiber |

Soft-bristle brush Car wash mitt |

| Every 60 Days | • Apply touch-up polish • Check sealant integrity • Clean hard-to-reach areas |

Foam applicator Detail brush set |

| Every 90 Days | • Full surface inspection • Reapply protective coating • Address minor oxidation |

Inspection light Coating kit |

This schedule adapts well to most environments. For coastal areas with salt air, shorten the 60-day tasks to monthly intervals.

Choose your aluminum’s armor wisely:

| Coating Type | Durability | Heat Resistance | Best For |

|---|---|---|---|

| Ceramic | 2-5 Years | 1,600°F+ | Show cars, marine hardware |

| Polymer | 9-16 Months | 400°F | Daily drivers, patio furniture |

| Carnauba Wax | 4-8 Weeks | 180°F | Temporary protection |

As noted in detailing studies, ceramic coatings reduce maintenance frequency by 60% but require meticulous application. For most homeowners, polymer sealants offer the best balance of cost and performance.

Preserve your finish with this 4-step process:

Critical Tip: Never let cleaners dry on surfaces – acidic residues accelerate corrosion. For anodized aluminum, stick to pH-neutral solutions and avoid circular scrubbing motions.

By pairing this maintenance rhythm with quality protective coatings, you’ll extend your aluminum’s shine between major polishing sessions. Next, we’ll explore how proper technique combines with premium materials for industrial-grade longevity.

What separates temporary sparkle from enduring radiance in professional aluminum finishing? As we've explored, achieving and maintaining mirror-like surfaces requires equal parts technique, quality materials, and adaptability. Let's crystallize the key insights that transform aluminum care from chore to craft.

Three pillars ensure long-lasting results:

Sunmay Aluminum elevates this equation through extruded profiles engineered for industrial aluminum polishing efficiency. Their T6-tempered surfaces with RA ≤0.8μm enable:

| Feature | Time Savings | Result Enhancement |

|---|---|---|

| Precision dimensional stability | 40% faster sanding | Even compound distribution |

| Anodizing-ready texture | 2-step sealing vs standard 4 | Reflectivity matching chrome |

While fundamentals remain constant, successful polishers adapt to:

We encourage testing different compounds and methods – Busch Super Shine's gel might revolutionize your wheel maintenance, while Zephyr's liquid polish could transform large panel work.

For those seeking materials that simplify the process, Sunmay's anodized aluminum products provide polish-ready surfaces with exceptional corrosion resistance. Their commitment to dimensional accuracy ensures every buffing stroke delivers maximum impact.

Remember: Great results begin with great materials. Choose wisely, polish meticulously, and protect relentlessly. Your aluminum surfaces will reward you with decades of dazzling service.

For professional results, use commercial compounds like Mothers Mag or Busch Super Shine. For DIY projects, baking soda paste or vinegar solutions work for light oxidation. Always match the polish to your aluminum alloy type - 6061 requires more aggressive compounds than 6063.

While WD-40 can provide temporary shine, it's not a permanent solution. For durable results, use specialized aluminum polishes that remove oxidation and create protective barriers. WD-40 works best as a quick touch-up between proper polishing sessions.

Apply temperature-resistant ceramic sealants or polymer coatings. Follow a 30-60-90 day maintenance schedule: monthly cleaning, bi-monthly touch-ups, and quarterly recoating. Avoid abrasive cleaners and store polished items away from corrosive chemicals.

Start with 220-400 grit sanding to remove deep oxidation, followed by progressive polishing with cutting compounds. For marine-grade aluminum, use oxidation neutralizers before final buffing. Severe cases may require professional restoration services.

DIY solutions like vinegar mixes work for light maintenance but lack durability. Commercial polishes outperform homemade recipes for heavy oxidation and long-term protection. Avoid abrasive kitchen pads - they can damage anodized coatings.

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on