Aluminum Profile Bending: Expert Guide to Machines and Techniques

Dec 31, 2024

Aluminum profile bending plays a pivotal role in modern manufacturing and construction, offering the ability to create complex shapes and structures with precision and efficiency. This technique is essential across various industries, including construction, automotive, and aerospace, where the demand for lightweight, durable materials continues to grow. By bending aluminum profiles, manufacturers can produce custom components that meet specific design and structural requirements, enhancing both functionality and aesthetics.

In the construction industry, aluminum profile bending is used to create architectural elements such as window frames, curtain walls, and decorative facades. These components not only contribute to the visual appeal of buildings but also offer structural benefits due to aluminum's strength and corrosion resistance. In the automotive sector, bent aluminum profiles are crucial in manufacturing lightweight vehicle frames and components, which help improve fuel efficiency and performance. Similarly, in aerospace, the ability to bend aluminum profiles allows for the production of parts that can withstand high stress and temperature variations, ensuring safety and reliability.

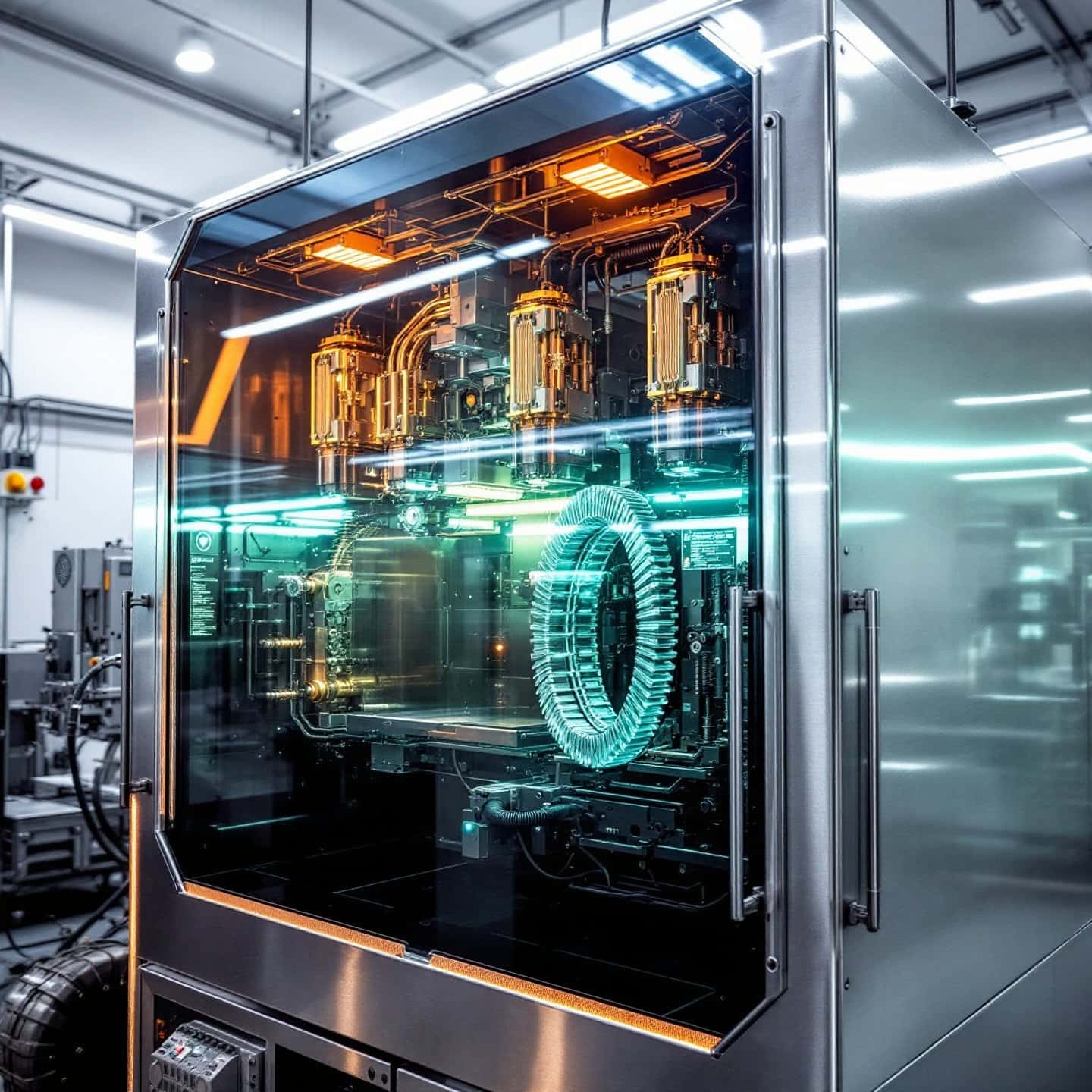

One of the most significant advancements in aluminum profile bending is the use of CNC bending machines. These machines offer unparalleled precision and consistency, automating the bending process to produce components with exact dimensions. CNC bending machines are particularly beneficial in high-volume production environments, where efficiency and accuracy are paramount. By selecting the appropriate CNC bending machine, manufacturers can optimize their production processes, reduce waste, and ensure the highest quality of bent aluminum profiles.

Understanding the nuances of aluminum profile bending and the capabilities of CNC bending machines is essential for industries aiming to leverage this technology for innovative applications. As we delve deeper into the techniques and machinery involved, it becomes clear that aluminum profile bending is not just a manufacturing process but a critical component of modern industrial design and engineering.

Aluminum profile bending is a transformative process that allows for the creation of custom aluminum shapes tailored to meet specific design requirements across various industries. This technique involves manipulating aluminum extrusions into precise forms without compromising the material's structural integrity. The ability to produce bent aluminum profiles is crucial in sectors such as architecture, transportation, and industrial design, where both functionality and aesthetics are paramount.

In architecture, bent aluminum profiles are used extensively to craft unique structural elements and decorative features. From the sweeping curves of modern building facades to the intricate designs of window frames and curtain walls, the flexibility of aluminum bending enables architects to push the boundaries of design. These structures not only captivate visually but also benefit from aluminum's lightweight and corrosion-resistant properties, ensuring longevity and durability.

Transportation industries, including automotive and aerospace, heavily rely on custom aluminum shapes to enhance performance and efficiency. In automotive design, for example, bent aluminum profiles contribute to lightweight vehicle frames, which improve fuel efficiency and reduce emissions. Similarly, in aerospace, these profiles are integral to manufacturing aircraft components that must endure extreme conditions while maintaining minimal weight. The high strength-to-weight ratio of aluminum makes it an ideal choice for such demanding applications.

Industrial design also benefits significantly from aluminum profile bending. Whether it's creating ergonomic furniture, sleek consumer electronics, or robust industrial machinery, the ability to mold aluminum into diverse shapes allows designers to achieve both aesthetic appeal and functional excellence. The adaptability of aluminum profiles to various forms supports innovation and customization in product development.

As industries continue to evolve, the demand for bent aluminum profiles and custom shapes grows, driven by the need for efficiency, sustainability, and design innovation. This adaptability, combined with aluminum's inherent properties, ensures that aluminum profile bending remains a cornerstone in the creation of modern, high-performance products.

When it comes to shaping aluminum profiles, the choice between manual and machine-assisted bending techniques can significantly impact the outcome of your project. Each method offers distinct advantages and limitations, making the decision largely dependent on the specific requirements and constraints of the task at hand.

Manual bending is a traditional approach that relies heavily on the skill of the operator. It involves using hand tools and simpler equipment to achieve the desired bends. This method is particularly beneficial for small-scale projects or custom designs where flexibility and cost-effectiveness are prioritized. Skilled operators can execute intricate bends, making manual bending ideal for unique, one-off designs. However, it is labor-intensive and can lead to inconsistencies in precision, especially in larger batches.

On the other hand, machine-assisted bending, particularly using CNC (Computer Numerical Control) technology, offers high precision and efficiency. CNC machines are programmed to perform complex bends with consistent accuracy, making them suitable for high-volume production. These machines excel in producing identical bends repeatedly, reducing the margin for error and saving time on large orders. The initial investment in CNC technology is higher, and it requires specialized training to operate, but the benefits in terms of precision and speed often outweigh these costs for large-scale projects.

Another critical consideration in aluminum profile bending is the choice between cold and hot bending processes. Cold bending involves shaping the aluminum at room temperature. This method is favored for projects requiring high precision and small curvature radii, such as precision instrument shells and mechanical components. However, cold bending can lead to a higher fracture rate and more deformation, which might affect the final product's uniformity.

Hot bending, conversely, is performed at elevated temperatures, which enhances the ductility of the aluminum, resulting in smoother curves and less deformation. This method is ideal for thick-walled components or when large bending angles are needed, such as in boiler tubes or steel plates. While hot bending allows for greater flexibility in shaping, it requires careful control of temperature to avoid compromising the material's integrity.

Understanding these techniques and their applications is crucial for selecting the most appropriate method for your aluminum profile bending needs. Whether prioritizing precision, volume, or complexity, each method offers unique benefits that can be leveraged to achieve optimal results.

In the realm of aluminum profile bending, selecting the right machine is crucial for achieving the desired precision and efficiency. Among the various types of bending machines available, CNC aluminum bending machines and arch bending machines stand out due to their advanced capabilities and versatility.

CNC aluminum bending machines are at the forefront of technology, offering unparalleled precision and automation in the bending process. These machines utilize computer numerical control (CNC) systems to automate bending tasks, allowing for high accuracy and repeatability. One of the key advantages of CNC machines is their ability to produce complex shapes and curves with minimal human intervention. This is particularly beneficial in industries such as construction, automotive, and aerospace, where precision is paramount.

With features like multi-axis functionality, CNC machines can perform intricate bends that involve multiple axes simultaneously. This capability is essential for creating components with complex geometries that would be challenging to achieve manually. The automation of these machines not only reduces the time required for setup but also increases overall production efficiency, making them ideal for high-volume manufacturing environments.

Furthermore, CNC bending machines are equipped with intuitive interfaces and user-friendly software, enabling operators to easily program and monitor the bending process. This ease of use reduces the learning curve for new operators and enhances productivity across the board. The versatility of CNC machines allows them to handle a wide range of aluminum profiles, making them a versatile choice for various applications.

Arch bending machines, specifically designed for creating curved structures, offer unique advantages in the bending process. These machines are particularly useful in applications requiring the bending of profiles into arcs or circular shapes, such as window frames, door frames, and other architectural elements. The ability to produce smooth, consistent curves is a hallmark of arch bending machines, making them indispensable for projects that demand aesthetic precision.

Equipped with specialized software, arch bending machines can handle a variety of profiles, including ordinary aluminum profiles, thermal-break profiles, and even complex aluminum-plastic combinations. The precision and flexibility of these machines allow for the bending of profiles into multiple radii, providing designers with the freedom to explore innovative architectural designs.

In addition to their precision, arch bending machines often come with features such as adjustable feeding speeds and customizable molds, which further enhance their adaptability to different project requirements. Their ability to maintain high positional accuracy ensures that each bend meets the exact specifications needed for structural integrity and visual appeal.

Understanding the capabilities of CNC aluminum bending machines and arch bending machines is essential for selecting the right equipment for your project. These machines not only enhance the efficiency of the bending process but also open up new possibilities for design and innovation in the use of aluminum profiles.

Choosing the right bending machine for aluminum profiles is a critical decision that impacts production efficiency, cost, and product quality. Whether you're dealing with small batches or large-scale operations, understanding the key considerations can guide you to the best machine for your needs.

When selecting a bending machine, start by assessing the material specifications of the aluminum profiles you intend to work with. Consider factors such as tensile strength, elongation, and thickness. These characteristics influence the type of machine that will best suit your needs. For instance, profiles with higher tensile strength require machines with greater force capabilities. Additionally, the desired bend radius is crucial; tighter radii may necessitate machines with advanced precision and control features.

Production volume is another essential factor. For high-volume production, CNC bending machines are often preferred due to their automation capabilities and precision, which reduce labor costs and increase throughput. However, if your production involves smaller batches or custom projects, manual or semi-automatic machines might be more cost-effective. Budget constraints also play a significant role. While CNC machines offer superior capabilities, they require a higher initial investment. Balancing cost with the desired machine features is key to maximizing return on investment.

To aid in the selection process, the following table provides a comparison of different aluminum profile bending machines, highlighting their bending capacity, automation level, and price range:

| Machine Model | Bending Capacity | Automation Level | Price Range |

|---|---|---|---|

| CNC Bending Machine A | High | Fully Automated | $$$ |

| Semi-Automatic Bender B | Medium | Semi-Automated | $$ |

| Manual Bending Tool C | Low | Manual | $ |

Each machine type offers distinct advantages. CNC machines provide precision and efficiency ideal for large-scale operations, while manual machines offer flexibility and lower costs for smaller projects. By carefully considering your specific needs and constraints, you can select a bending machine that aligns with your production goals and budget.

For those seeking high-quality aluminum profiles and bending solutions, Suqian Sunmay Aluminium offers a diverse range of products tailored to meet various industrial needs. Their expertise in crafting premium aluminum alloys ensures superior performance and durability, making them a reliable partner for your bending projects. Explore their offerings to find the perfect solution for your applications.

When it comes to sourcing aluminum bending machines, selecting the right manufacturer is crucial to ensuring quality and efficiency in your production processes. Several companies have established themselves as leaders in this field, offering a range of machines equipped with advanced features and reliable performance.

Choosing the right supplier goes beyond just the initial purchase. Here are some critical factors to consider:

By thoroughly evaluating potential suppliers and considering these factors, you can make an informed decision that aligns with your operational needs and budget. For premium aluminum profiles and bending solutions, Suqian Sunmay Aluminium stands out as a trusted partner, offering high-quality products and exceptional customer service.

When investing in aluminum profile bending machines, understanding the cost implications is vital for achieving a balance between initial expenditure and long-term benefits. The price of these machines can vary significantly based on several factors, including the type, size, and features of the machine.

The cost of bending machines is primarily influenced by their complexity and capabilities. For instance, CNC aluminum bending machines, known for their precision and automation, typically command a higher price due to their advanced technology and efficiency. These machines are an excellent choice for high-volume production environments where precision is crucial, but their higher cost must be justified by the production needs and potential savings in labor and material waste.

On the other hand, manual bending tools represent a more affordable option, suitable for small-scale or custom projects where flexibility and low initial investment are priorities. However, they may incur higher labor costs over time due to their reliance on skilled operators and longer production times.

When considering the purchase of a bending machine, it's essential to evaluate the long-term value versus the upfront cost. Machines with higher automation levels, such as those with CNC controls, often have a higher initial price but can lead to significant savings in operational costs due to reduced labor requirements and increased production speed. According to a professional overview , these machines can enhance productivity and reduce material waste, offering a better return on investment over time.

Additionally, maintenance and repair costs should be factored into the total cost of ownership. Regular upkeep is necessary to maintain optimal performance, and investing in a machine from a reputable manufacturer can reduce these expenses by ensuring durability and reliability.

Ultimately, the decision should align with your production requirements and budget constraints. Consider the specific needs of your operation, such as the volume of production, the complexity of the bends required, and the available budget. By carefully analyzing these factors, you can select a machine that not only fits your immediate needs but also provides long-term value, ensuring a sound investment in your production capabilities.

For businesses looking to maximize their investment, understanding the nuances of bending machine costs and their long-term benefits is crucial. Whether opting for a high-end CNC machine or a more economical manual tool, the key is to ensure that the chosen machine aligns with your operational goals and offers the best value for your investment.

As we've explored throughout this guide, aluminum profile bending is a critical process that underpins a wide range of industrial applications, from architecture to automotive manufacturing. The decision to select the appropriate bending technique and machinery is not merely a technical choice but a strategic one that can significantly impact the efficiency, cost-effectiveness, and quality of your production processes.

When considering your options, it's essential to assess the specific requirements of your project. Factors such as material specifications, desired bend radius, production volume, and budget constraints should guide your decision-making process. Whether opting for the precision of CNC machines or the flexibility of manual methods, understanding the strengths and limitations of each option will empower you to make informed decisions that align with your operational goals.

For those seeking premium aluminum profile solutions, Suqian Sunmay Aluminium stands out as a leader in the industry. With a commitment to quality and innovation, Suqian Sunmay Aluminium offers a diverse range of high-quality aluminum alloys and cutting-edge technologies designed to meet the most demanding specifications. Their expertise in crafting custom aluminum profiles ensures that you can achieve superior bending results tailored to your specific needs. To explore their offerings and discover how they can support your projects, visit Suqian Sunmay Aluminium .

Ultimately, the key to successful aluminum profile bending lies in a thorough understanding of your project's unique demands and the capabilities of the bending solutions available. By leveraging the insights and guidance provided in this guide, you can confidently navigate the complexities of aluminum profile bending and unlock new possibilities for innovation and excellence in your industry.

Yes, aluminum profiles can be bent using various techniques like CNC and manual bending, allowing for precise custom shapes in industries such as architecture and automotive.

Cold bending is often preferred for precision and smaller radii, while hot bending is suitable for larger angles and thicker profiles due to improved ductility.

The best method depends on the project. CNC bending offers high precision for complex shapes, while manual bending is cost-effective for smaller batches.

Yes, 80/20 aluminum profiles can be bent, but the process requires careful handling to maintain structural integrity and achieve the desired form.

Consider factors like material specifications, desired bend radius, production volume, and budget. CNC machines are ideal for high-volume precision work.

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on