In modern industry and daily life, aluminum profiles hold a significant position due to their unique advantages and wide-ranging applications. From building structures to electronic products, from transportation to home decoration, aluminum profiles are ubiquitous, bringing innovation and convenience to various fields. This article will delve into the many aspects of aluminum profiles, including their characteristics, applications, and production processes, providing a comprehensive understanding of this multifunctional material.

Aluminum profiles are highly favored due to their excellent characteristics.

The density of aluminum is relatively low, at only 2.7g/cm³, which is about one-third that of steel. However, through alloying and processing techniques, aluminum profiles can achieve high strength. This combination of lightweight and high strength makes them irreplaceable in weight-sensitive fields such as aerospace and automotive manufacturing. For example, in aircraft manufacturing, the use of aluminum profiles can effectively reduce the weight of the aircraft, lower energy consumption, and improve flight performance. Common aviation aluminum alloy profiles, after special treatment, can meet the stringent requirements of aircraft structural components. For instance, 6061 aluminum alloy profiles have a tensile strength of over 200MPa and are widely used in aircraft wings and fuselage frames. In the automotive industry, aluminum alloy wheels are a typical application of the lightweight and high-strength characteristics of aluminum profiles. Compared to traditional steel wheels, aluminum alloy wheels can reduce weight by 20%-30%, not only lowering fuel consumption but also enhancing vehicle handling performance. Additionally, in some automotive repair equipment, low-profile aluminum jacks, 3-ton low-profile aluminum jacks, and aluminum profile low-profile jacks also utilize the lightweight and high-strength characteristics of aluminum profiles, making them easy to operate and move.

Aluminum quickly forms a dense oxide film in the air, which prevents further erosion of the aluminum substrate by oxygen and moisture, giving aluminum profiles excellent corrosion resistance. Whether in humid coastal areas or corrosive industrial environments, aluminum profiles can maintain good performance. For example, aluminum alloy doors and windows for building exteriors, after anodizing treatment, can remain as good as new for many years in outdoor environments without rusting or corroding. In the chemical industry, some pipelines that transport corrosive liquids or gases also use aluminum profiles. Through special surface treatments, such as fluorocarbon spraying, the corrosion resistance is further enhanced, ensuring the safe operation of the pipelines. Moreover, aluminum window profiles, as an important component of building doors and windows, also benefit from the corrosion resistance of aluminum, ensuring long-term use.

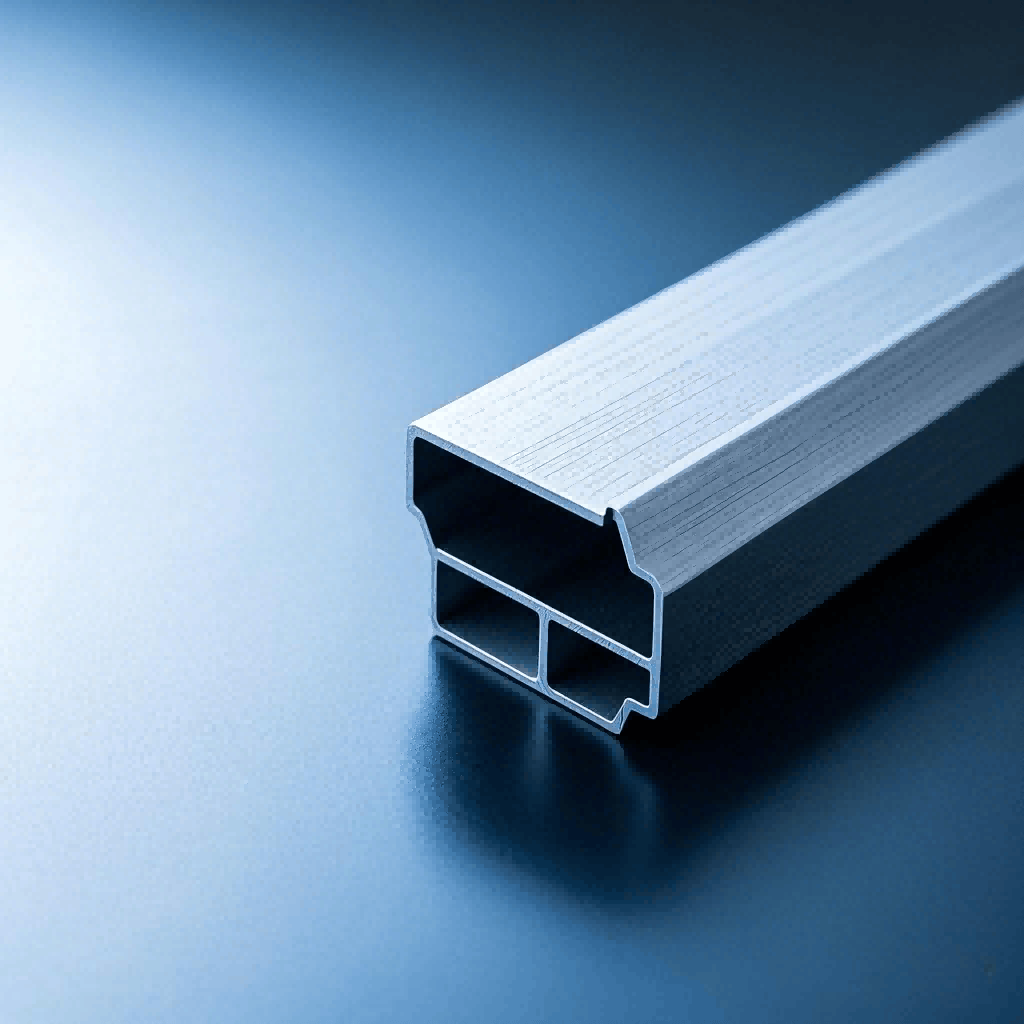

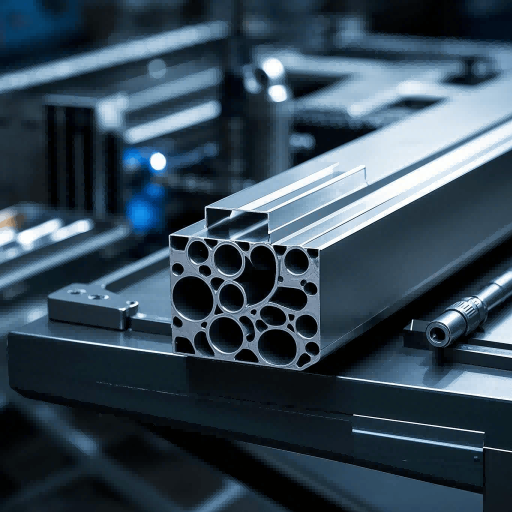

Aluminum profiles have good plasticity and can be processed into various complex shapes through extrusion, forging, rolling, and other methods. Extrusion is a common method for producing aluminum profiles. By extruding aluminum billets through a die at high temperatures, various cross-sectional shapes of profiles can be obtained, such as common rectangular, circular, and irregular shapes. This processing performance allows aluminum profiles to meet diverse design needs in different fields. In home decoration, common aluminum alloy curtain rods and decorative lines are produced through extrusion. These aluminum profile products are not only aesthetically pleasing but also easy to install, adding unique decorative effects to home environments. In the field of electronic devices, the casings of computers and mobile phones often use aluminum profiles. Through precise processing, aluminum profile casings can be made thin, light, and strong, while also providing good heat dissipation for internal electronic components. For example, LED aluminum profiles, as an important component of LED lamps, are made through aluminum profile extrusion, effectively dissipating heat and ensuring the normal operation of the lamps. Additionally, aluminum profiles can be bent or processed into T-slot shapes to meet different usage needs. In some special equipment, such as aluminum profile simulation drills, the good processing performance of aluminum profiles is also utilized to make corresponding components.

The excellent characteristics of aluminum profiles have led to their wide application in many fields.

Aluminum alloy doors and windows, with their advantages of aesthetics, energy efficiency, and good sealing performance, have become the mainstream choice for modern building doors and windows. The profiles of aluminum alloy doors and windows are carefully designed to effectively block wind and rain, provide sound insulation, and offer thermal insulation, creating a comfortable indoor environment. At the same time, curtain walls, as an important form of modern building exterior decoration, also rely heavily on aluminum profiles. Curtain wall aluminum profiles usually have large cross-sectional sizes and high strength, supporting large areas of glass or stone panels to create beautiful and grand building exteriors. For example, many large commercial buildings and office buildings use aluminum profile frames for their curtain walls. The Shanghai Oriental Pearl Tower, for instance, uses a large amount of high-quality aluminum profiles in its structure, ensuring the building's stability while showcasing a unique modern aesthetic. During the installation of doors, windows, and curtain walls, equipment such as aluminum low-profile self-dumping trailers may be used to transport and install aluminum profiles.

In interior decoration, aluminum profiles also have rich applications. Aluminum alloy ceilings, with their lightweight, fireproof, moisture-proof, and easy-to-clean characteristics, are widely used in kitchens, bathrooms, and offices. Additionally, aluminum alloy skirting boards and decorative lines can add a sense of refinement and layering to indoor spaces. For example, in some high-end hotel decorations, aluminum alloy decorative lines are cleverly used on the edges of walls and ceilings, enhancing the overall decoration level. Aluminum profiles are also widely used in various aspects of interior decoration, providing strong support for creating beautiful and comfortable indoor environments.

With the increasing demand for energy saving and emission reduction in the automotive industry, aluminum profiles are increasingly used in automotive manufacturing. In addition to the aforementioned aluminum alloy wheels, car body frames, engine blocks, and radiators also extensively use aluminum profiles. Using aluminum profiles for car body frames can significantly reduce the weight of the car, improving fuel economy and handling performance. For example, some new energy vehicles use all-aluminum body structures to increase range, significantly reducing body weight. Tesla's models, for instance, use a large amount of aluminum profiles to achieve lightweight bodies, thereby improving battery efficiency and extending range. In the automotive manufacturing process, extruded aluminum profiles and aluminum extrusion profiles are widely used in the production of various components.

In the field of rail transportation, the bodies and interiors of subway and high-speed rail vehicles also widely use aluminum profiles. The lightweight characteristics of aluminum profiles help reduce the energy consumption of trains, while their good corrosion resistance ensures the safety and reliability of trains during long-term operation. Train bodies are usually made by welding large extruded aluminum profiles, providing high strength and good sealing performance. Interior components such as seats, handrails, and luggage racks are also often made of aluminum profiles, being both aesthetically pleasing and practical. For example, China's high-speed trains use a large amount of high-strength aluminum alloy profiles, not only improving train speed but also providing passengers with a comfortable and safe travel environment.

With the trend of miniaturization and thinning of electronic devices, aluminum profiles have become an ideal material for the casings of computers and mobile phones. Aluminum profile casings not only provide good protection for internal electronic components but also ensure the stability of electronic devices during long-term operation through their good heat dissipation performance. For example, Apple's MacBook series laptops use high-quality aluminum alloy profiles for their casings. After precision processing and surface treatment, these casings are not only stylish but also have excellent heat dissipation. In the mobile phone industry, many flagship models use aluminum alloy frames or full aluminum bodies, enhancing the texture and grip of the phones.

With the continuous improvement of electronic device performance, heat dissipation has become increasingly important. Aluminum profiles, with their good thermal conductivity, are widely used in the manufacture of heat sinks for electronic devices. Aluminum profile heat sinks are usually made through extrusion, producing products with complex heat dissipation fin structures that effectively increase the heat dissipation area and improve efficiency. Whether it's CPU heat sinks for computers or LED lamp heat sinks, aluminum profiles play an important role. For example, in computer hosts, the aluminum profile heat sinks used for CPUs can quickly dissipate the heat generated by the CPU, ensuring stable operation and preventing performance degradation due to overheating.

Aluminum profile production requires a series of complex processes.

Raw Material Preparation: The main raw material for producing aluminum profiles is aluminum ingot. Depending on the specific alloy requirements, additional metals such as copper, magnesium, and silicon are added in precise proportions. Before entering the melting furnace, these materials undergo strict quality checks and pretreatment to ensure their purity and composition meet production standards.

Melting Process: The pre-treated raw materials are placed in the melting furnace, where they are heated to a high temperature. During the melting process, temperature, time, and furnace atmosphere must be strictly controlled to ensure the alloy composition is uniform and stable. Additionally, refining agents are used to remove impurities and gases from the molten aluminum, improving its quality.

Casting Process: The molten aluminum is cast into ingots through casting methods such as semi-continuous casting and continuous casting. Semi-continuous casting involves cooling and solidifying the aluminum liquid in a crystallizer to form ingots of a certain length. Continuous casting, an extension of semi-continuous casting, allows for continuous ingot production, improving efficiency. The quality of the ingots directly affects the subsequent processing and product quality of aluminum profiles.

Mold Design and Manufacturing: Extrusion molds are key tools in aluminum profile production. The design and manufacturing precision of the mold directly impact the cross-sectional shape and dimensional accuracy of the aluminum profiles. Mold design involves precise calculations and optimization to meet customer needs and product requirements. The manufacturing of molds uses high-precision equipment to ensure quality and longevity. For specific aluminum profiles, such as 20x100 aluminum extrusions, mold design and manufacturing need to be even more precise.

Extrusion Process: The ingots are heated to an appropriate temperature and then placed in the extrusion machine, where they are pushed through the mold by an extrusion ram to create the desired profile shape. Parameters such as extrusion speed, temperature, and pressure must be carefully controlled to ensure the quality and performance of the aluminum profiles. Lubrication techniques are sometimes used during extrusion to improve surface quality.

Anodizing: Anodizing is one of the most common surface treatments for aluminum profiles. By applying an anodic current to the surface of the aluminum profile, a hard and dense aluminum oxide film forms. This film not only enhances corrosion and wear resistance but also allows for coloring and decorative effects. Anodized aluminum profiles are widely used in the construction and decoration industries.

Electrophoretic Coating: Electrophoretic coating involves immersing aluminum profiles in a bath of organic resin, where an electric current causes the resin to deposit evenly onto the surface. This process forms a protective coating. Electrophoretic-coated aluminum profiles have smooth, flat surfaces and excellent weather resistance and corrosion protection, making them ideal for high-end products such as doors, windows, and curtain walls.

Powder Coating: Powder coating involves applying dry powder coatings through electrostatic adsorption, followed by high-temperature curing to form a durable coating. Powder coatings offer a variety of colors and textures and provide strong corrosion resistance and adhesion, making them suitable for both construction and industrial applications.

When selecting aluminum profiles, it's important to ensure the product meets high-quality standards.

Reputable aluminum profile manufacturers will provide product quality certificates that include details such as the chemical composition, mechanical properties, and surface treatment of the aluminum profiles. By reviewing the certificate, you can verify whether the profiles meet relevant standards and requirements. For example, for building aluminum profiles, you should check whether they comply with the national standard GB 5237 "Aluminum Alloy Building Profiles." Some high-quality aluminum extrusion catalogs also list detailed product quality information and standards.

High-quality aluminum profiles should have smooth, even surfaces without noticeable scratches, pits, or bubbles. Anodized aluminum profiles should have a uniform and dense oxide layer. Electrophoretic and powder-coated aluminum profiles should have strong, even coatings with no streaks or missed areas. When selecting products, you can feel the surface for smoothness and carefully inspect for defects.

Choosing a manufacturer with a solid reputation and production capabilities is crucial for ensuring the quality of aluminum profiles. Manufacturers with strong capabilities typically have advanced production equipment, comprehensive quality management systems, and professional technical teams that can produce high-quality aluminum profiles. You can gather information about manufacturers through the internet or industry reviews. For instance, our company has years of experience in the aluminum profile production field, equipped with advanced production processes and stringent quality control systems. Our products are reliable and trusted by clients.

With continuous technological progress and changing market demands, the aluminum profile industry is also exhibiting new development trends.

To meet the higher material performance requirements in high-end fields such as aerospace and new energy vehicles, the research and development of high-performance aluminum profiles has become an important direction for industry growth. For example, developing aluminum alloys with higher strength, better toughness, and stronger heat resistance, as well as improving processing techniques to enhance the overall performance of aluminum profiles.

With the growing awareness of environmental protection, aluminum profile manufacturers are increasingly focusing on green and eco-friendly production. They are adopting energy-efficient production equipment and processes to reduce energy consumption and pollutant emissions during manufacturing. Additionally, there is a focus on recycling and reusing waste aluminum profiles, contributing to resource circularity.

With the advancement of Industry 4.0, smart manufacturing is gradually being applied in the aluminum profile industry. By introducing automated equipment, robots, and information management systems, the industry is achieving intelligent control and management of production processes. This helps increase production efficiency, enhance product quality, and reduce manufacturing costs.

Aluminum alloys are materials formed by adding other alloy elements to aluminum. Aluminum profiles, on the other hand, are products created by processing aluminum alloys through specific techniques such as extrusion and rolling, resulting in products with defined cross-sectional shapes and sizes. Simply put, aluminum alloy is the raw material, while aluminum profile is the finished product after processing the alloy.

The price of aluminum profiles is mainly influenced by the fluctuation in aluminum ingot prices, alloy composition, processing techniques, surface treatments, and market supply-demand relationships. Aluminum ingot price is the base cost; the more complex the alloy composition, the more intricate the processing techniques, and the higher the surface treatment requirements, the higher the price of aluminum profiles. Market supply and demand also have a significant impact on prices, as prices may rise during periods of high demand and decrease when demand is low.

For aluminum profile windows and doors, regular maintenance mainly involves keeping the surface clean. It is recommended to wipe with a clean soft cloth and avoid using corrosive cleaners. For light stains, a neutral cleaner can be used. For outdoor aluminum profiles, it is important to regularly check the connection parts for looseness, and promptly repair and tighten them if necessary.

In general, ordinary aluminum profiles may experience strength degradation when used in high-temperature environments. However, some high-temperature aluminum alloy profiles, which undergo special alloying and heat treatment processes, can maintain good performance under certain high-temperature conditions. When choosing aluminum profiles for high-temperature applications, it is important to select the appropriate aluminum alloy and product based on specific temperature and usage requirements.

Through the comprehensive introduction of aluminum profiles above, we hope you now have a deeper understanding of them. Whether in industrial fields or daily life, aluminum profiles bring numerous benefits and innovations with their unique advantages. If you have any aluminum profile-related needs, feel free to visit our company website, where we will provide high-quality products and professional services.

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on