Sunmay's aluminum profiles surface treatment methods are: Polished, Anodized, Colored, Brushed, E-Coat, Matte, Sandblasted.

The colors are: Champagne Gold, Bronze, Black, Red, Yellow, Golden, Blue, Rose Gold, Pink, Champagne Color, Silver, Bright Finish, Purple.

Material & Temper :

Custom Aluminum Alloy with Heat TreatmentApplication :

Architectural, Decorative Home and Industrial Aluminum ProfilesLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Anodized CoatedColor :

BlackPackaging method :

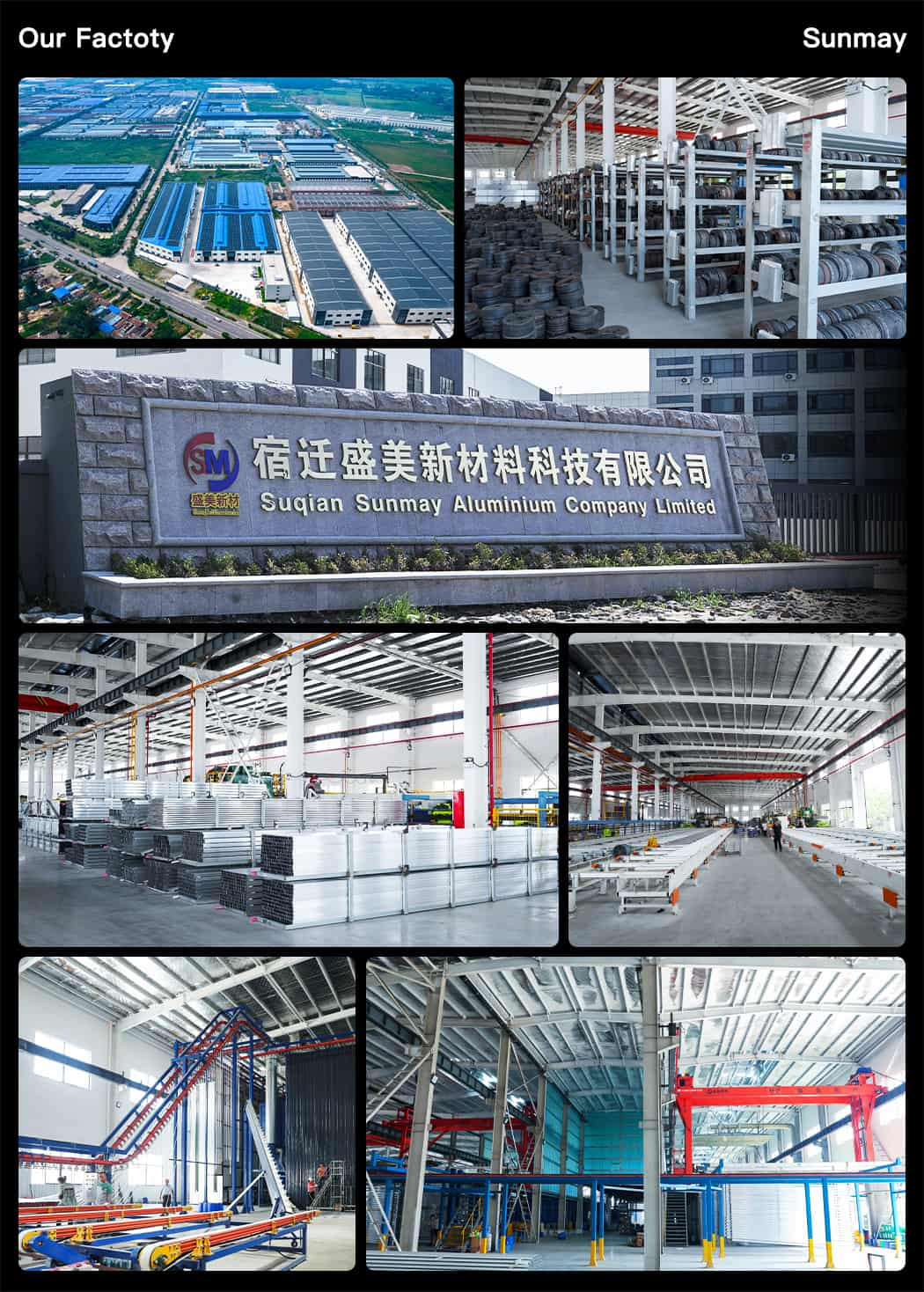

Customized according to customer requirementsSuqian Sunmay Aluminium Company Limited, a renowned specialist in the aluminum profiles industry, excels in crafting premium-quality aluminum alloys across an extensive range, including 5052, 6063, 6061, 6060, 6082, 6005, 6201, 6463, 7001, and 7075, with tempering options of T4, T5, and T6 to suit diverse applications. Equipped with cutting-edge technology, our forward extrusion presses feature a maximum sectional diameter capacity of 700mm and the capability to produce ultra-thin walls with precision down to 0.25mm. Additionally, our reverse extrusion machines and drawing facilities empower us to fabricate seamless and high-precision aluminum tubes.

Dedicated to surface excellence, we provide a comprehensive array of treatments, such as anodizing (with both coloring and dyeing capabilities), powder coating, wood grain transfer, polishing, and brushing, all of which enhance the aesthetic appeal and durability of our products. With vast experience in adhering to standards like GB5237, TS16949, EN12020, EN755, and EN573, we ensure compliance with international benchmarks.

Our diverse portfolio caters to various sectors, encompassing architectural aluminum profiles, industrial aluminum solutions, and automotive aluminum components. With a global reach spanning over 50 countries, our architectural aluminum profiles have garnered significant international acclaim, particularly lauded by distributors in more than 20 nations.

Grounded in the values of "Customer-Centered, Commitment Fulfilled," we are relentless in our dedication to exceeding customer expectations. Visionary in our endeavors, we aspire to achieve "Leading Cost-Effectiveness in China's Aluminium Industry," continually innovating and optimizing to deliver unparalleled value to our clients worldwide.

FACTORY VIEW

Black Anodized Coated Aluminum Door Frame Extrusion is a specially treated aluminum profile. Through the anodizing process, a hard oxide film is formed on the surface of the aluminum, and then dyed to give it a deep black appearance. This material not only retains the original lightness, high strength and corrosion resistance of the aluminum profile, but also adds a unique aesthetic effect, making it stand out in many application scenarios.

First, it is an aluminum profile with the basic characteristics of aluminum; second, it has been anodized, which enhances the surface hardness and wear resistance of the aluminum; third, through the dyeing process, the surface of the aluminum is given a uniform and deep black, which not only enhances the visual effect of the material, but also increases its corrosion resistance; finally, this material is often used in construction or decoration fields such as door frames, and is favored for its elegant appearance and superior performance.

Anodized aluminum profiles have the following advantages:

1. Corrosion resistance: The generated oxide film significantly improves the corrosion resistance of the substrate.

2. Wear resistance: The oxide film makes the surface harder and prolongs the service life.

3. Decorative: The oxide film has good adsorption and can be dyed into various colors to increase the aesthetics.

4. Environmental protection: The electrolyte used in the anodizing process is relatively simple and has less pollution to the environment.

With its unique beauty and superior performance, Black Anodized Coated Aluminum Door Frame Extrusion has become an indispensable part of modern design and manufacturing. Whether in the field of architecture, home or industry, it has shown great potential and application value. I believe that in the future development, this material will continue to play an important role and create a better living environment for us.

Lead time: 10 to 30 days.

Executable Quality Standard: GB5237 Or per customer-specified quality standards.

Moq: 1 ton for each order

OEM&ODM: Acceptable

Email: sales@sunmayalu.com

Mob/Whatsapp/Wechat: 17366266559

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on