Exploring the Versatility of Aluminum Tubing: Sizes, Applications, and Customization

Nov 26, 2024

Aluminum tubing stands out as a remarkably versatile material, playing a pivotal role across a multitude of industries due to its unique combination of lightweight and robust characteristics. This adaptability makes it an ideal choice for applications ranging from aerospace engineering to artistic endeavors. The inherent properties of aluminum tubing, such as its exceptional strength-to-weight ratio, corrosion resistance, and ease of fabrication, allow it to meet the demands of diverse sectors, including construction, automotive, and even creative fields like sculpture and design.

In the aerospace industry, for example, aluminum tubing is indispensable. It is used extensively in aircraft structures, fuel lines, and hydraulic systems, where it ensures both efficiency and safety. This is largely due to its ability to maintain structural integrity while significantly reducing weight, a critical factor in aviation. Similarly, in the construction sector, aluminum tubing is often utilized for frameworks and supports, offering durability and flexibility in design.

Beyond standard applications, aluminum tubing is also favored for its customization potential. Manufacturers can produce tubing in various shapes and sizes, tailored to specific project requirements. This includes round, square, and even complex hollow designs, as noted by Profile Precision Extrusions, a leader in manufacturing high-quality extruded aluminum tubing (source) . Such customization options allow industries to leverage aluminum tubing's versatility to address unique challenges and innovate within their respective fields.

This article will delve into the different sizes, applications, and customization possibilities of aluminum tubing, providing a comprehensive understanding of how this versatile material can be optimized for various uses. Whether you're an engineer, architect, or DIY enthusiast, understanding the full potential of aluminum tubing can lead to more efficient and creative solutions.

When it comes to selecting the right aluminum tubing for a project, understanding the available sizes is crucial. Aluminum tubing sizes can vary significantly, each offering unique benefits that cater to specific applications. This versatility in sizing is one of the reasons aluminum tubing is a preferred choice across various industries.

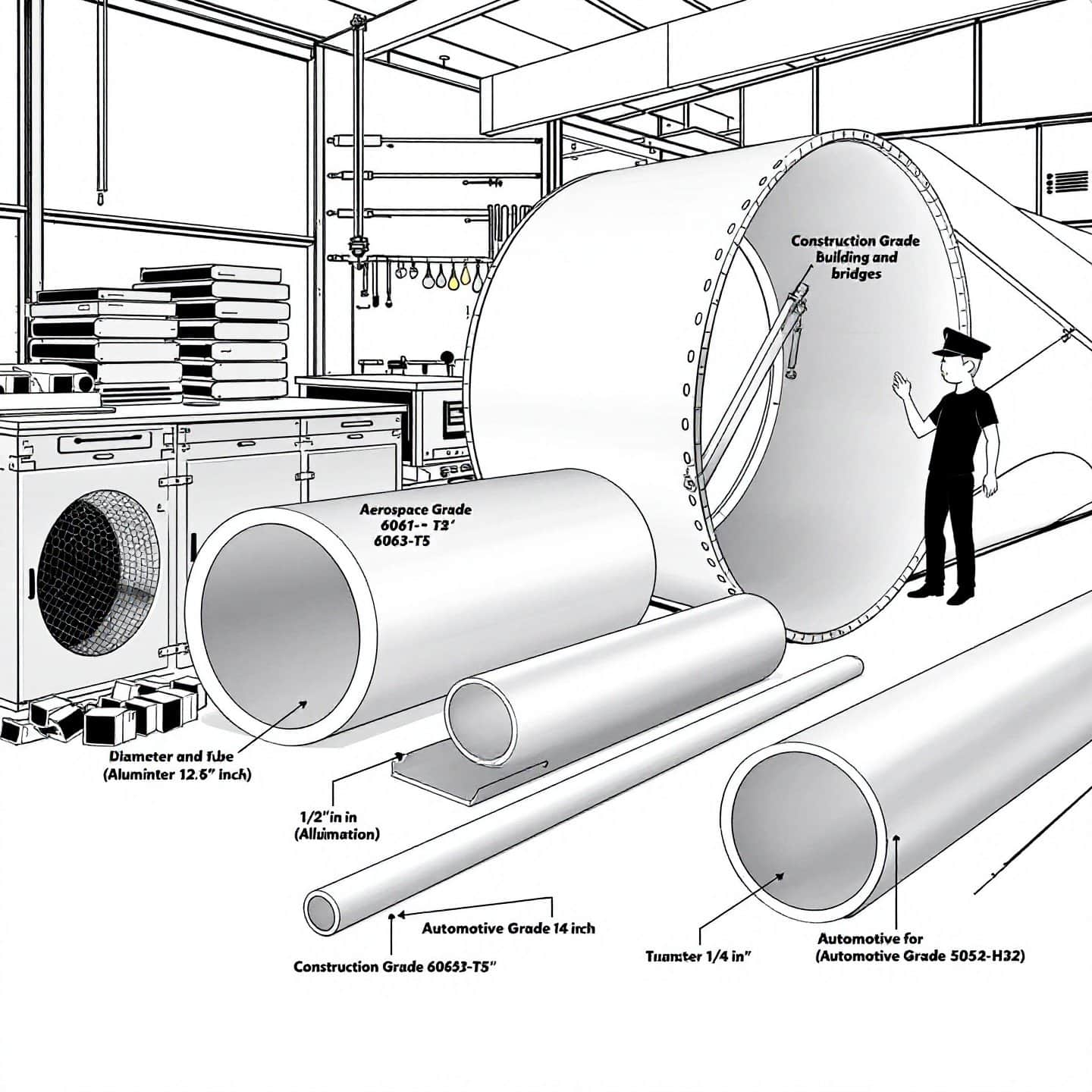

Standard aluminum tubing sizes range from as small as 1/8 inch to as large as 12-3/4 inches in outer diameter (OD), with wall thicknesses that can be adjusted according to the required strength and application (source) . The size of the tubing directly influences its strength, weight, and flexibility. For instance, a larger diameter tube with a thicker wall is typically stronger and can bear more load, making it suitable for structural applications in construction or heavy machinery.

Conversely, smaller diameter tubes with thinner walls are lightweight and more flexible, ideal for applications where weight reduction is critical, such as in the aerospace and automotive industries. These tubes can be used in fuel lines, hydraulic systems, and other components where maintaining a lightweight structure without compromising strength is essential. The ability to tailor the size and thickness of aluminum tubing allows engineers and designers to meet precise specifications, ensuring optimal performance and efficiency.

The choice of aluminum tubing size also affects its application flexibility. Smaller tubes are often used in intricate designs or where space is limited, such as in electronic enclosures or medical devices. Larger tubes, on the other hand, are preferred for frameworks and structural supports due to their ability to handle greater stress and load.

Moreover, the size of the tubing can influence its ease of installation and integration into existing systems. For example, in the construction industry, using a standard size can simplify the assembly process and reduce costs associated with custom fittings.

In summary, understanding the various aluminum tubing sizes and their specific applications is vital for optimizing the material's utility. Whether for lightweight components or sturdy structural elements, selecting the appropriate size ensures that the tubing performs efficiently and meets the demands of the intended application. For a general introduction to aluminum tubing, including its types and applications, see our comprehensive guide to aluminum tubing.

Round tube aluminium is a staple in numerous industries, celebrated for its unique blend of strength, flexibility, and corrosion resistance. This form of aluminum tubing is particularly favored in sectors such as automotive, construction, and design, where its properties can be leveraged to enhance both functionality and aesthetics.

In the automotive industry, round tube aluminium is used extensively in the manufacture of vehicle frames, exhaust systems, and heat exchangers. Its lightweight nature contributes significantly to fuel efficiency, while its strength ensures the durability and safety of automotive components. Additionally, its corrosion resistance makes it ideal for parts exposed to harsh environmental conditions, such as road salts and moisture.

The construction industry also benefits greatly from round tube aluminium. Its structural integrity makes it perfect for frameworks, scaffolding, and supports. Architects and builders often choose aluminum tubes for their projects due to their ability to withstand substantial loads without adding excessive weight. This is particularly beneficial in skyscraper construction, where reducing structural weight can lead to considerable cost savings.

Beyond these traditional applications, round tube aluminium is a favorite in the design and creative sectors. Its ease of manipulation allows for innovative designs in furniture, lighting fixtures, and artistic installations. Designers appreciate its sleek appearance and the modern aesthetic it can bring to projects, making it a popular choice for contemporary architecture and interior design.

Round tubes offer distinct advantages over other shapes, such as square or rectangular tubes. One of the primary benefits is their ability to distribute stress evenly across their surface. This characteristic is particularly important in applications where structural integrity under load is critical. The circular shape also minimizes wind resistance, making round tubes ideal for structures exposed to high wind conditions.

Moreover, the manufacturing process for round tube aluminium allows for seamless construction, enhancing their strength and reducing the likelihood of weak points that can occur in welded seams. This seamless construction is particularly advantageous in high-pressure applications, such as hydraulic systems and pipelines.

In summary, the versatility and benefits of round tube aluminium make it an invaluable material across various industries. Its combination of lightweight strength, corrosion resistance, and ease of fabrication ensures it remains a top choice for engineers, architects, and designers alike. As we continue to explore the potential of aluminum tubing, understanding the specific advantages of round tubes can lead to more efficient and innovative applications.

Aluminum tube stock is a critical resource for a variety of industries, offering flexibility and efficiency for numerous applications. Essentially, aluminum tube stock refers to pre-manufactured tubes that are readily available for immediate use, allowing for swift project execution and adaptability to changing demands. This stock is available in several standard shapes, including round, square, and rectangular forms, each suited to different applications based on their structural properties.

Aluminum tube stock can be sourced from a wide range of suppliers, including specialized metal distributors and manufacturers. Companies like Hydro Extrusion and Metal Supermarkets provide extensive inventories of aluminum tubing in various alloys and sizes, catering to specific industry needs (source) . These suppliers often offer both standard and custom options, ensuring that clients can find the precise specifications required for their projects.

In addition to local suppliers, online platforms have become increasingly popular for purchasing aluminum tube stock. These platforms provide the convenience of browsing extensive catalogs and ordering directly from a website, often with detailed specifications and availability information. This accessibility ensures that businesses can maintain a steady supply of aluminum tubing, even in remote locations.

Maintaining an inventory of aluminum tube stock is crucial for industries that require quick project turnarounds. In sectors like construction, automotive, and aerospace, having immediate access to necessary materials can significantly reduce downtime and increase productivity. For instance, construction projects often face tight deadlines, and any delay in material availability can lead to costly setbacks. By keeping ample stock, companies can ensure that they are prepared to meet project demands without interruption.

Moreover, the versatility of aluminum tube stock allows it to be used in a wide array of applications, from structural frameworks to intricate components in machinery. This adaptability means that having a diverse stock on hand can provide a competitive edge, enabling businesses to swiftly respond to market changes and customer requirements.

In summary, aluminum tube stock plays a vital role in facilitating efficient operations across various industries. Its availability and the strategic maintenance of inventory ensure that businesses can meet project demands promptly and effectively, leveraging the inherent advantages of aluminum tubing to stay ahead in competitive markets.

Custom aluminum tubing offers a unique advantage for industries requiring precision and flexibility in their projects. Unlike standard tubing, custom solutions allow for specific tailoring to meet unique specifications, providing enhanced performance and efficiency. This adaptability is crucial in sectors where design intricacies and specialized requirements are paramount.

One of the primary benefits of custom aluminum tubing is its ability to meet precise project specifications. This customization ensures that the tubing fits perfectly within the intended design, reducing the need for additional modifications or adjustments. Furthermore, custom tubing can be fabricated to include specific features such as unique bends, diameters, and wall thicknesses, which are essential for specialized applications.

Custom aluminum tubing also helps in optimizing material usage, as it can be produced in exact lengths and shapes required for a project, minimizing waste and reducing costs. This efficiency is particularly beneficial in large-scale manufacturing or construction projects where material savings can lead to significant cost reductions.

Several industries benefit from the tailored solutions offered by custom aluminum tubing. In the automotive sector, for instance, custom tubing is used to create lightweight yet durable components, such as exhaust systems and structural elements, which enhance vehicle performance and fuel efficiency.

The aerospace industry also relies heavily on custom aluminum tubing to meet the stringent requirements of aircraft design and performance. Tubing must withstand high pressures and temperatures while maintaining minimal weight, making custom solutions ideal for such demanding environments.

Additionally, the architectural and construction industries utilize custom aluminum tubing for innovative designs and structural elements. The ability to bend and shape tubing into intricate forms allows architects to push the boundaries of traditional design, creating visually striking and functional structures. Looking for advice on buying aluminum tubing for your custom projects? Don’t miss our article on how to buy aluminum tubing.

Working with experienced manufacturers like Suqian Sunmay Aluminium Company Limited ensures access to high-quality custom aluminum tubing. With advanced technology and a commitment to precision, Sunmay Aluminium offers a range of customization options, including various alloys and tempering treatments, to meet diverse project needs. Their expertise in producing seamless and high-precision tubes further enhances the reliability and performance of custom tubing solutions.

In conclusion, custom aluminum tubing provides unparalleled flexibility and efficiency for projects across multiple industries. By leveraging the expertise of specialized manufacturers, businesses can ensure that their custom tubing solutions meet the highest standards of quality and performance, ultimately leading to successful project outcomes.

When browsing for aluminium tubing for sale, identifying quality products is crucial to ensure the success and safety of your projects. With a wide variety of options available, making an informed choice requires understanding key quality indicators and matching the tubing to your specific needs.

To distinguish high-quality aluminum tubing from inferior products, there are several factors to consider:

Once you've identified quality tubing, the next step is selecting the type that best suits your project's requirements:

By carefully evaluating these factors, you can confidently select the right aluminum tubing for your needs, ensuring both efficiency and reliability in your projects. As you explore various options for aluminium tubing for sale, keeping these tips in mind will help you make informed decisions that align with your specific applications and quality standards.

Purchasing aluminium tube stock in bulk can be a cost-effective strategy for businesses that require large quantities of this versatile material. However, bulk buying requires careful planning to ensure that the stock is stored properly and remains in excellent condition until it's needed. Here are some key considerations and tips for purchasing and storing aluminium tube stock efficiently.

Proper storage of aluminium tube stock is essential to prevent damage and preserve its quality. Here are some recommended storage solutions:

To maintain the integrity of your aluminium tube stock, consider the following tips:

By implementing these strategies, businesses can effectively manage their aluminium tube stock, ensuring that they are well-prepared to meet project demands while minimizing waste and maximizing efficiency.

Alum tubing, often a shorthand reference for aluminum tubing, represents a versatile and essential component across numerous industries. However, the term can sometimes lead to confusion, particularly when buyers encounter similar materials like steel or copper tubing. Understanding the distinct properties and advantages of alum tubing is crucial for making informed purchasing decisions.

One of the standout features of alum tubing is its lightweight nature, which is approximately one-third the weight of steel. This characteristic makes it an ideal choice for applications where weight reduction is critical, such as in aerospace and automotive industries. Despite its lightness, alum tubing offers impressive strength and durability, which is essential for maintaining structural integrity in demanding environments.

Another significant advantage is its corrosion resistance. Aluminum forms a natural oxide layer that protects it from environmental degradation, making it suitable for outdoor applications and harsh conditions. This property is particularly beneficial in marine environments or in locations with high humidity, where other materials might fail.

Potential confusion often arises when buyers are faced with terms like "alum tubing" and "aluminum tubing," which are essentially the same but may be perceived differently due to regional or industry-specific jargon. Furthermore, alum tubing's malleability and ease of fabrication set it apart from more rigid materials like steel, offering greater flexibility in design and application.

It's also important to distinguish alum tubing from its alloy variations. Different aluminum alloys, such as 6061 or 5052, provide varying benefits in terms of strength, weldability, and thermal conductivity. Buyers should be aware of these distinctions to select the right type of alum tubing for their specific needs.

Alum tubing finds extensive use in construction, where its strength-to-weight ratio enhances efficiency and reduces costs. It is also prevalent in the manufacturing of consumer goods, from bicycles to furniture, where its aesthetic appeal and ease of maintenance are highly valued. In electronics, its excellent conductivity makes it a preferred choice for components requiring efficient thermal management.

In conclusion, understanding the unique properties of alum tubing and its various applications can significantly benefit buyers looking to optimize their projects. By recognizing its lightweight, corrosion-resistant, and versatile nature, industries can leverage alum tubing to achieve innovative and efficient solutions.

Alu tube, a common abbreviation for aluminum tube, is celebrated for its lightweight properties, making it a preferred choice in industries where mobility and ease of installation are paramount. The term 'alu tube' often surfaces in contexts that demand high strength-to-weight ratios, such as in transport, construction, and portable structures.

The primary advantage of alu tube is its remarkable lightness compared to other materials like steel. This quality is crucial in applications where reducing the overall weight of a structure can lead to significant benefits. For instance, in the transportation industry, lighter materials contribute to improved fuel efficiency and performance. This is particularly evident in the automotive and aerospace sectors, where every pound saved can translate into substantial economic and environmental savings.

Moreover, alu tube's ease of installation is another significant benefit. Its lightweight nature simplifies handling and assembly, reducing labor costs and time. This is especially beneficial in construction projects where quick and efficient assembly is critical, such as in temporary structures or modular buildings.

In the construction industry, alu tube is frequently used in frameworks and scaffolding due to its ability to support substantial loads while remaining easy to transport and erect. Its corrosion resistance also ensures longevity, even in challenging outdoor environments. In the realm of portable structures, such as tents and exhibition stands, alu tube's lightweight and durable nature makes it an ideal choice, allowing for easy setup and dismantling.

In addition, the use of alu tube in the design and manufacturing of bicycles and sporting equipment highlights its versatility. The demand for lightweight yet strong materials in these areas underscores alu tube's suitability, providing enhanced performance without compromising durability.

In summary, the alu tube stands out in industries that prioritize mobility and ease of installation. Its lightweight properties, combined with strength and durability, make it an indispensable component in modern engineering and design. As industries continue to evolve, the role of alu tube in facilitating innovative and efficient solutions is likely to expand, reaffirming its position as a material of choice for lightweight applications.

Tubular aluminum is a material that uniquely balances strength and lightness, making it indispensable across various high-demand industries. Its appeal lies in its ability to offer substantial structural integrity while maintaining a lightweight profile, a critical factor in applications where weight is a paramount concern.

Aluminum's strength-to-weight ratio is one of its most celebrated attributes. Compared to steel, aluminum is significantly lighter—about one-third the weight—yet it can still provide comparable strength, especially when alloyed with other elements. This property is crucial in industries like aerospace, where reducing weight without sacrificing strength can lead to enhanced fuel efficiency and performance. According to AAA Air Support , the round shape of tubular aluminum further enhances its strength, offering higher resistance to flex and torsional twisting than square tubes of similar weight.

In the aerospace industry, tubular aluminum is extensively used in the construction of aircraft frames, fuselages, and wings. Its ability to withstand high stress while reducing overall aircraft weight contributes to increased payload capacity and improved flight range. The 6061-T6 aluminum alloy, known for its excellent weldability and corrosion resistance, is a popular choice in this sector due to its optimal performance under extreme conditions.

Structural projects also benefit significantly from the use of tubular aluminum. Its application in building frameworks and support structures is well-documented, providing architects and engineers with a versatile material that can be adapted to various architectural designs. The material's corrosion resistance, as highlighted by Service Steel , ensures longevity and durability, even in harsh environmental conditions, making it ideal for both indoor and outdoor constructions.

Beyond traditional applications, tubular aluminum is finding new roles in innovative fields such as renewable energy and advanced manufacturing. Its lightweight and durable nature makes it suitable for components in solar panels and wind turbines, where efficiency and longevity are critical. As technology advances, the potential for tubular aluminum in emerging applications continues to grow, reinforcing its status as a material of choice for engineers and designers aiming for sustainable and efficient solutions.

In conclusion, the combination of strength and lightweight properties makes tubular aluminum a versatile and valuable material across numerous industries. Its continued evolution and adaptation to new technologies promise an exciting future for this remarkable material.

Bending aluminum tubing, known in French as "cintrage tube aluminium," is a critical process utilized across various industries, from automotive to construction. The challenge lies in bending the tubing without compromising its structural integrity, a task that requires precision and the right techniques.

There are several methods for bending aluminum tubing, each suited to different applications and material specifications. The choice of method depends on factors such as the tubing's diameter, wall thickness, and the desired bend radius.

Bent aluminum tubing is indispensable in various sectors:

In conclusion, mastering the techniques of bending aluminum tubing is vital for industries that rely on its strength and versatility. By choosing the appropriate bending method, manufacturers can ensure that the tubing meets both functional and aesthetic requirements, enhancing the overall quality and performance of the final products.

Aluminum tubing's remarkable versatility makes it an invaluable resource across numerous industries. Its ability to be tailored in various sizes and shapes, coupled with its lightweight yet robust characteristics, allows it to meet diverse application needs. Understanding these aspects is crucial for maximizing its utility in any project.

The selection of appropriate sizes and shapes of aluminum tubing is foundational to its effective use. From small-diameter tubes for intricate applications to large-diameter ones for structural support, each size serves a specific purpose. Round tubes, with their ability to distribute stress evenly, are ideal for applications requiring structural integrity under load, while square and rectangular tubes offer unique benefits in architectural designs. Choosing the right combination of size and shape ensures that the tubing performs optimally in its intended application.

Customization options further enhance the versatility of aluminum tubing. Tailoring the tubing to meet specific project requirements can significantly improve performance and efficiency. Industries such as aerospace, automotive, and construction benefit from custom solutions that address unique challenges, such as weight reduction and increased strength. By opting for custom aluminum tubing, businesses can achieve precise specifications, reduce material waste, and ultimately lower costs.

For those seeking high-quality custom solutions, partnering with experienced manufacturers like Suqian Sunmay Aluminium Company Limited can be invaluable. Sunmay Aluminium's expertise in crafting premium aluminum alloys and providing a range of surface treatments ensures that clients receive tailored solutions that meet the highest standards of quality and performance. Their commitment to innovation and precision makes them a preferred choice for custom aluminum tubing needs.

In conclusion, by understanding the various sizes, shapes, and customization options available, businesses and individuals can fully leverage the advantages of aluminum tubing. Whether for lightweight applications or robust structural projects, aluminum tubing offers a versatile and efficient solution. As industries continue to evolve, the ability to maximize the utility of aluminum tubing will remain a key factor in achieving innovative and successful outcomes. Consider exploring specialized options to meet your unique project requirements and enhance the overall effectiveness of your designs.

While aluminum tubing is lighter, it offers excellent strength-to-weight ratio, making it ideal for applications where reducing weight is crucial, such as in aerospace and automotive industries. Though not as strong as steel, its corrosion resistance and versatility provide unique advantages.

Aluminum tubing can be cut using a hand or power saw equipped with a metal cutting blade. Ensure the blade is suitable for metal to achieve smooth cuts, which is crucial for maintaining the tubing's structural integrity.

2x2 aluminum tubing typically has a tensile strength of 62,000 PSI and yield strength of 46,000 PSI, making it suitable for structural applications requiring moderate strength and lightweight properties.

The main difference lies in thickness and application. Aluminum pipes usually have a consistent thickness and are used for transporting fluids, while tubes vary in thickness and are used for structural purposes.

Custom aluminum tubing allows for precise specifications, enhancing performance and reducing waste. Industries like aerospace and automotive benefit from tailored solutions that meet specific design and strength requirements.

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on