Master Aluminum T-Tracks: Essential Guide for Woodworking and Industrial Use

Dec 11, 2024

Aluminum T-tracks have become indispensable in both woodworking and industrial settings, offering a unique blend of versatility and precision that enhances project outcomes. These components are essentially T-shaped slots made from high-quality aluminum, designed to be mounted on various surfaces such as workbenches, router tables, and jigs. Their primary function is to facilitate the use of accessories like clamps, stops, and fences, allowing for adjustable and customizable workstations.

The importance of aluminum T-tracks in woodworking cannot be overstated. They provide a stable and secure platform essential for achieving accurate and repeatable cuts, which is crucial for both amateur hobbyists and professional craftsmen. By integrating T-tracks into your workspace, you can significantly improve your workflow, ensuring that each task is performed with greater precision and efficiency.

In industrial applications, aluminum T-tracks are equally valuable. They are used to build adjustable workstations, machine frames, and safety guards, showcasing their adaptability in rapidly changing manufacturing environments. This adaptability is a key reason why T-tracks are favored in settings that demand quick adjustments and high precision.

The purpose of this guide is to delve into the multifaceted uses of aluminum T-tracks, exploring their benefits and offering insights into selecting the right track for your specific needs. Whether you're enhancing a woodworking project or optimizing an industrial process, understanding the potential of T-tracks can lead to more efficient and successful outcomes. As you navigate this guide, you’ll discover how these versatile components can transform your projects, providing the tools needed for precision and efficiency.

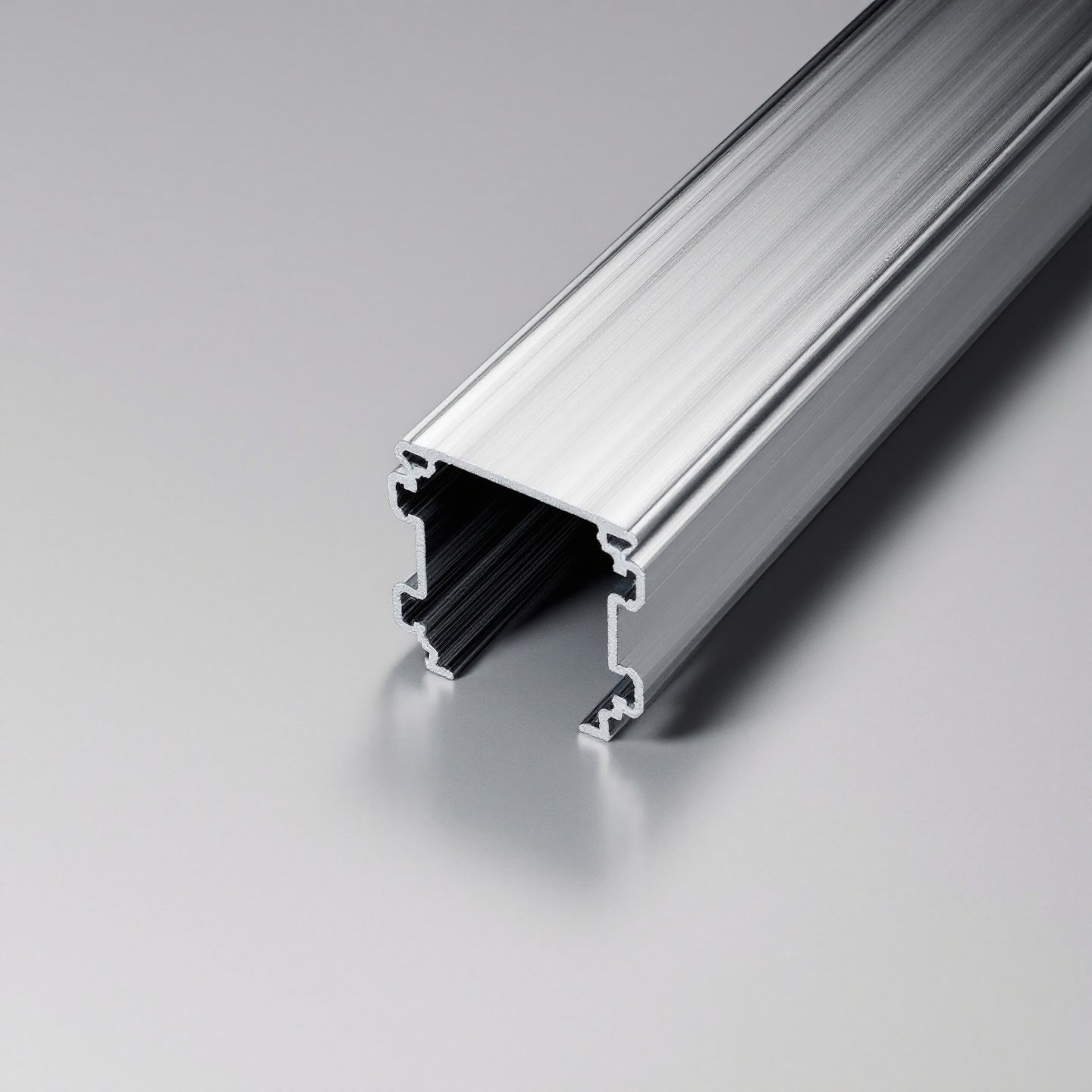

Aluminum T-tracks are an essential component in both woodworking and industrial applications, known for their unique T-shaped profile that allows for versatile and adjustable setups. But what exactly are these tracks, and how do they function? Let's delve into the aluminum T-track definition and explore their functionality.

An aluminum T-track is an extruded aluminum profile that features a T-shaped slot. This slot is designed to accommodate various accessories such as bolts, nuts, and connectors, enabling users to create highly adjustable and customizable workstations, jigs, and fixtures. These tracks are typically available in multiple lengths and widths, making them suitable for a wide range of applications.

The primary T-track functionality lies in its ability to facilitate quick adjustments and secure attachments. For instance, in woodworking, T-tracks can be embedded into router tables or drill press tables, allowing users to attach stops or hold-downs with ease. This setup not only enhances precision but also significantly improves workflow efficiency by reducing the time needed to set up and adjust various components.

One of the standout features of aluminum T-tracks is their role in improving workflow and flexibility, which is invaluable in both amateur and professional settings. Imagine you’re working on a complex woodworking project; the ability to quickly adjust your setup using T-tracks means you can maintain momentum and focus on the creative aspects of your work rather than getting bogged down by technical adjustments.

In industrial environments, the adaptability of T-tracks is equally beneficial. They are often used to build adjustable workstations and machine frames, providing a flexible solution that can be reconfigured as project demands change. This adaptability is particularly advantageous in manufacturing settings where rapid adjustments are necessary to maintain production efficiency.

In summary, aluminum T-tracks are more than just a tool—they are a pivotal element in enhancing the efficiency and precision of various projects. Whether you're a hobbyist looking to refine your woodworking techniques or a professional aiming to optimize industrial processes, understanding the structure and functionality of T-tracks is crucial. As we move forward, we'll explore their specific applications in woodworking, highlighting how these tracks can transform your workspace into a more efficient and precise environment.

In the realm of woodworking, aluminum T-tracks have emerged as indispensable tools, transforming ordinary workspaces into highly efficient and customizable environments. These tracks are ingeniously designed to support a wide array of applications, from enhancing router tables to optimizing jigs and fixtures. Let's explore how T-tracks can revolutionize your woodworking projects.

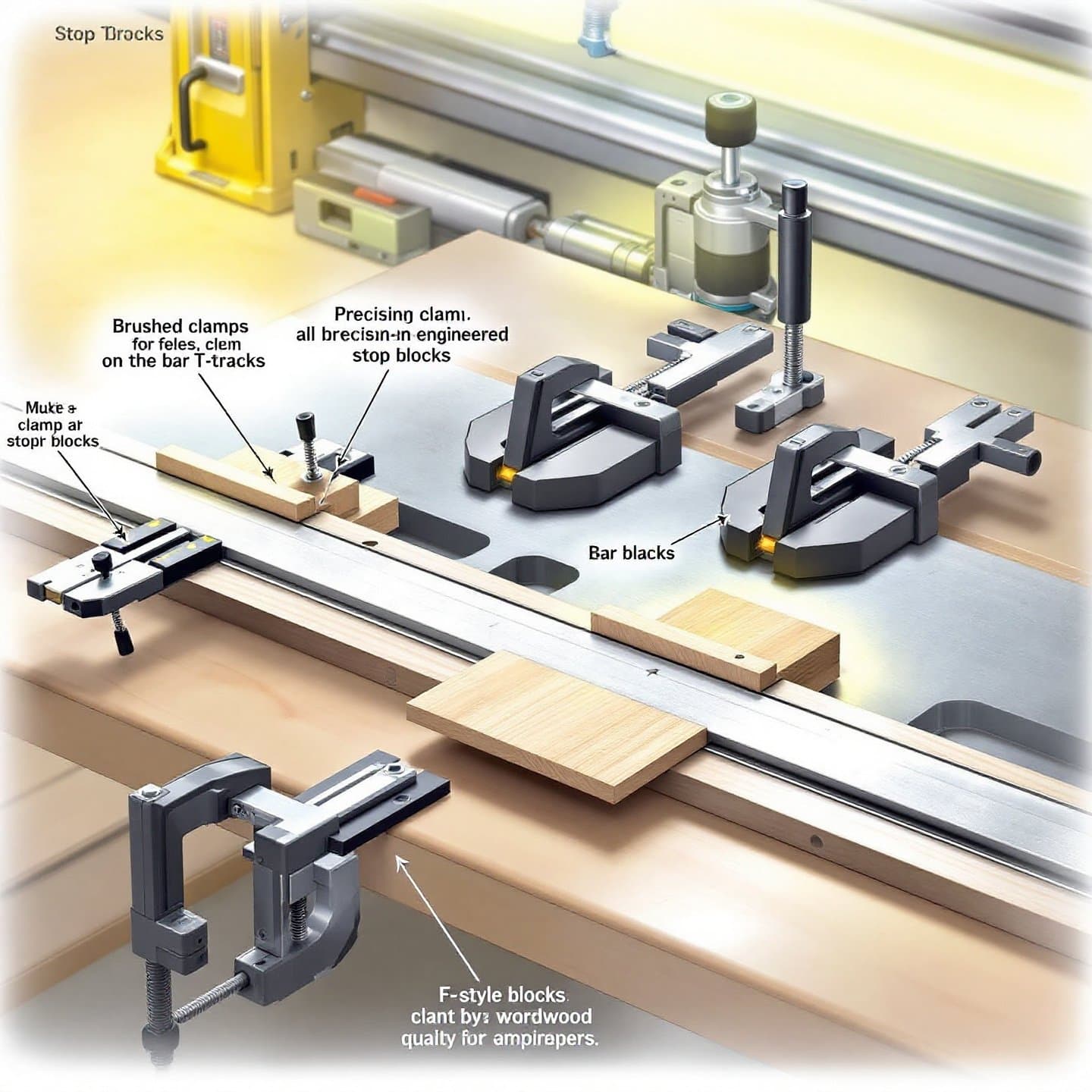

One of the most common T-track woodworking applications is their integration into router tables and drill press tables. By embedding T-tracks into these surfaces, woodworkers can easily attach and adjust stops, hold-downs, and fences. This setup not only ensures precision in cuts and drills but also allows for quick alterations, saving valuable time during complex projects. For instance, when working on a series of identical pieces, T-tracks facilitate consistent alignment, ensuring each piece meets exact specifications.

Jigs and fixtures are essential for achieving repeatable accuracy, and T-tracks play a crucial role in their customization. By incorporating T-tracks, woodworkers can create adjustable jigs that accommodate different project sizes and shapes. This adaptability is particularly beneficial when crafting intricate designs or when the project demands frequent changes. Imagine being able to swiftly modify your jig setup to accommodate a new project dimension without having to build a new fixture from scratch—T-tracks make this a reality.

Another significant advantage of T-tracks is their ability to support versatile clamping solutions. Whether you're securing a workpiece for cutting or holding components in place during assembly, T-tracks provide the flexibility to position clamps exactly where needed. This capability is especially useful in tasks requiring multiple clamps or in situations where traditional clamping methods are impractical.

In conclusion, the integration of T-tracks into your woodworking setup offers a myriad of benefits, enhancing both the precision and efficiency of your projects. As we continue, we'll delve into how these tracks are utilized in industrial settings, further showcasing their versatility and adaptability.

In the fast-paced world of manufacturing, the ability to quickly adapt to changing demands is crucial. Aluminum T-tracks, known for their durability and versatility, have become a vital component in creating agile and efficient industrial environments. Let's delve into the industrial T-track uses and how these tracks are revolutionizing manufacturing processes.

One of the primary applications of aluminum T-tracks in industrial settings is the construction of adjustable workstations. These tracks allow for the seamless integration of various components, such as shelves, tool holders, and lighting fixtures, which can be easily repositioned to suit different tasks. This flexibility is essential for accommodating diverse workflows and optimizing space utilization, ensuring that each workstation can be tailored to meet specific production needs.

Another significant application is in the construction of machine frames. T-tracks provide a robust framework that can support heavy machinery while allowing for easy modifications and expansions. This capability is particularly beneficial in industries where machinery needs to be frequently reconfigured or upgraded to keep pace with technological advancements.

Safety is a paramount concern in industrial environments, and T-tracks play a crucial role in enhancing workplace safety. By integrating T-tracks into safety guard systems, manufacturers can create barriers that are not only strong and reliable but also adjustable. This adjustability ensures that safety measures can be quickly adapted to new equipment or changes in the production line, maintaining a safe working environment without compromising on efficiency.

| Application | Benefits |

|---|---|

| Adjustable Workstations | Enhances flexibility, optimizes space, and adapts to workflow changes. |

| Machine Frames | Supports heavy loads, allows for easy reconfiguration, and facilitates upgrades. |

| Safety Guards | Provides strong, adjustable barriers that enhance safety and efficiency. |

In summary, aluminum T-tracks are indispensable in modern manufacturing, offering solutions that enhance flexibility and efficiency. As industries continue to evolve, the adaptability of T-tracks will remain a key asset, enabling manufacturers to respond swiftly to new challenges and opportunities. As we move forward, we'll explore how to choose the right T-track for your needs, ensuring you can fully leverage their potential in both woodworking and industrial applications.

When it comes to selecting T-track for your projects, making the right choice can significantly impact the efficiency and precision of your work. Whether you're a woodworker looking to enhance your workshop or an industrial professional seeking to optimize your production line, understanding the key factors in choosing the right T-track is crucial. Here’s a detailed T-track buying guide to help you navigate the selection process.

One of the first considerations when selecting a T-track is its size. T-tracks commonly come in widths of 3/4 inch and thicknesses of 3/8 or 1/2 inch, as noted in Popular Woodworking . It's essential to ensure that the T-track's dimensions are compatible with your existing tools and work surfaces. For instance, if you plan to integrate T-tracks into a router table, verify that the track fits seamlessly into the pre-existing slots or dadoes.

Material quality is another critical factor. Most T-tracks are made from extruded aluminum, which offers a balance of strength and lightweight properties. However, the specific grade of aluminum can vary, affecting durability and performance. Opt for high-grade aluminum T-tracks to ensure they can withstand the rigors of frequent use, especially in industrial settings where heavy-duty applications are common.

Consider the mounting options available for the T-track. Pre-drilled tracks with countersunk holes, as highlighted by Popular Woodworking , are easier to install and provide a secure fit. This feature is particularly beneficial when you need to cut the track to a specific length, ensuring that you still have adequate mounting points. Additionally, tracks with glue grooves can be advantageous for installations where screwing isn't feasible.

By keeping these considerations in mind, you can choose a T-track that not only meets your current needs but also offers flexibility for future projects. As we continue, let's explore some of the top brands and products in the market, providing you with further insights into making the best choice for your specific applications.

When it comes to selecting the best aluminum T-tracks, the market offers a variety of brands, each with unique features and benefits. This section aims to guide you through some of the most reputable brands and their popular products, helping you make an informed decision based on your specific needs and budget.

Several brands have established themselves as leaders in the aluminum T-track industry, known for their quality and reliability. Among these, Rockler and Powertec stand out for their comprehensive range of products and strong customer satisfaction.

| Brand | Product | Features | Price Range | Customer Rating |

|---|---|---|---|---|

| Rockler | Universal T-Track | High precision, durable aluminum, pre-drilled holes | $$$ | 4.8/5 |

| Powertec | Aluminum T-Track | Cost-effective, compatible with #8 screws, metallic finish | $$ | 4.5/5 |

As observed, both Rockler and Powertec offer excellent products, each catering to different market segments. Rockler is ideal for those who prioritize precision and are willing to invest more for premium quality. In contrast, Powertec appeals to those seeking value without sacrificing essential features.

Customer feedback plays a crucial role in evaluating product performance. Rockler's T-tracks are frequently praised for their precision and ease of installation, as highlighted in woodworking forums and reviews. On the other hand, Powertec's products receive commendations for their affordability and satisfactory performance, with many users appreciating the cost savings without a significant drop in quality.

In conclusion, choosing the right T-track involves balancing your budget with the specific requirements of your projects. Both Rockler and Powertec offer reliable options that cater to different needs, ensuring that you can find a product that aligns with your expectations. As we proceed, we'll discuss how to maintain these tracks to ensure their longevity and optimal performance.

Proper maintenance and care are crucial for ensuring that your aluminum T-tracks remain in excellent condition, providing reliable performance over time. While these tracks are known for their durability, regular upkeep can prevent issues such as corrosion and wear, which can impact their functionality. Here, we explore effective T-track maintenance strategies to help you get the most out of your investment.

Keeping your T-tracks clean is essential for smooth operation. Start by using a mild spray cleaner, such as Fantastic, to remove surface dirt and dust. Lightly spray the track and use a soft brush, like a fingernail brush, to gently scrub away debris. Avoid soaking the tracks in water to prevent rusting. After cleaning, wipe the tracks dry with a terrycloth towel to eliminate any moisture.

If you notice any light surface rust, a light application of WD-40 can help remove it. Spray a small amount on the affected area and wipe it clean with a separate towel. Ensure that the tracks are completely dry to prevent further rust formation. Regular cleaning not only maintains the tracks' appearance but also enhances their performance by reducing friction during use.

Proper storage is another key aspect of caring for T-tracks . Store your tracks in a dry environment to prevent exposure to moisture, which can lead to rusting. If possible, keep them in a storage rack or on a shelf where they are not at risk of being bent or damaged. Avoid stacking heavy items on top of the tracks, as this can cause them to warp or become misaligned.

To ensure your T-tracks remain in optimal condition, conduct regular inspections and follow a simple maintenance checklist:

By following these maintenance tips and regularly inspecting your T-tracks, you can extend their lifespan and maintain their efficiency. Proper care not only preserves the functionality of your tracks but also ensures they continue to support your projects effectively. As we conclude our guide, we'll summarize the benefits and applications of aluminum T-tracks and introduce a leading provider in the market.

Aluminum T-tracks have proven themselves as indispensable tools across both woodworking and industrial sectors, offering unmatched precision, versatility, and efficiency. From enhancing router tables and drill press setups to constructing adjustable workstations and safety guards, the applications of T-tracks are vast and varied. These tracks not only streamline workflows but also allow for customized solutions tailored to specific project needs, making them a valuable addition to any toolkit.

As you embark on optimizing your projects, consider the many aluminum T-track benefits that can elevate your craftsmanship and operational efficiency. They provide a stable platform for precise adjustments, reduce setup times, and enhance safety, ultimately leading to superior project outcomes. The ability to optimize T-track use lies in selecting the right track for your needs, ensuring compatibility with your tools and work environment.

In the pursuit of high-quality aluminum profiles, Suqian Sunmay Aluminium stands out as a leading provider. Their commitment to crafting premium-quality aluminum alloys, backed by cutting-edge technology, sets them apart in the industry. With a diverse range of products and a dedication to customer satisfaction, Suqian Sunmay Aluminium continues to innovate, offering solutions that meet the evolving demands of global markets.

Whether you are a seasoned professional or an enthusiastic hobbyist, integrating aluminum T-tracks into your projects can unlock new levels of precision and efficiency. As you explore the possibilities, remember that the right tools can transform your work, turning challenges into opportunities for excellence. Embrace the versatility of aluminum T-tracks and discover how they can enhance your projects, ensuring success with every endeavor.

Aluminum T-tracks offer significant strength with a tensile strength of around 38,000 psi, making them suitable for various industrial and woodworking applications. Their lightweight yet durable nature supports heavy-duty use without compromising on performance.

T-slot aluminum is used in building adjustable workstations, machine frames, and safety guards in industrial settings. Its modular design allows for easy assembly and reconfiguration, making it ideal for dynamic environments that require frequent adjustments.

Welding T-slot aluminum is generally unnecessary due to its modular design, which allows for assembly using simple hand tools. This feature enhances flexibility and reduces the need for permanent alterations, making it a versatile choice for various applications.

Consider factors like size compatibility with existing tools, material quality, and mounting options. Opt for high-grade aluminum for durability and ensure the track fits your specific project requirements for optimal performance.

Aluminum T-tracks enhance precision and efficiency in woodworking by providing customizable setups for tools and accessories. They enable quick adjustments, improve workflow, and support versatile clamping solutions, making them invaluable for both amateurs and professionals.

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on