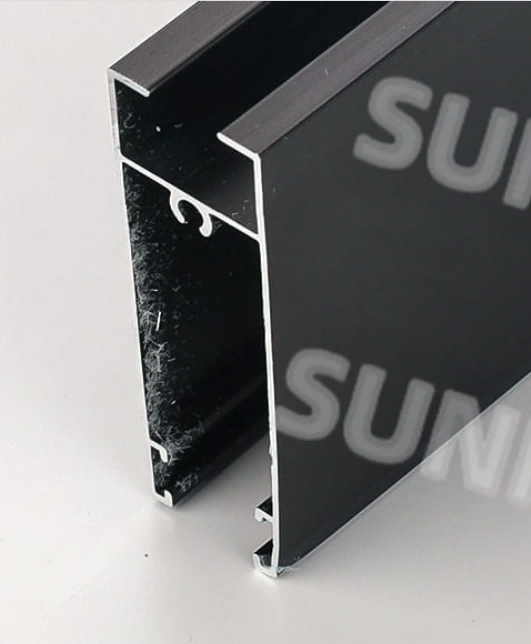

Matte black coated anodized aluminum extrusions offer a stylish, durable and corrosion-resistant solution for industrial and architectural applications, ideal for structural framing, custom fittings and architectural elements.

Material & Temper :

Custom Aluminum Alloy with Heat TreatmentApplication :

Architectural, Decorative Home and Industrial Aluminum ProfilesLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Matte Coated AnodizedColor :

BlackPackaging method :

Customized according to customer requirementsThe Matte Black Coated Anodized Aluminium Extrusion is a top-tier product designed to offer exceptional performance and aesthetics for a wide range of industrial and architectural applications. This matte black aluminum extrusion combines the durability of anodized aluminum with a sleek matte black finish, creating a highly resistant and attractive solution for various uses. Whether you’re designing custom components, structural frameworks, or architectural elements, this extrusion offers the strength and aesthetic appeal needed for modern projects.

Key Features

Matte black aluminum extrusion: The matte black finish provides a sophisticated, modern look while offering increased resistance to wear, corrosion, and environmental factors.

Anodized finish: The anodizing process enhances the aluminum’s surface, providing superior protection against corrosion and extending the material’s lifespan.

Versatility: This extrusion is highly adaptable, ideal for use in a wide variety of applications including custom fittings, architectural structures, and machinery components.

Durability: With its anodized surface, the coated aluminum extrusion profiles exhibit enhanced durability and strength, ensuring long-lasting performance even under demanding conditions.

Advantages

Enhanced Corrosion Resistance: The anodized finish on the matte black aluminum extrusion offers superior protection against corrosion, ensuring that the product maintains its appearance and performance for years, even in harsh environments.

Aesthetic Appeal: The sleek matte black coating provides a contemporary, professional look that suits a variety of design themes, from industrial to modern architecture, making it the ideal choice for both functional and decorative purposes.

Strength and Durability: Anodized aluminum is known for its robustness, and this anodized aluminum profile black extrusion offers superior strength, making it perfect for structural applications, custom fittings, and more.

Low Maintenance: The anodized surface is highly resistant to scratches and stains, making maintenance minimal. Cleaning is easy, and the product retains its visual appeal with little effort.

Applications

The coated aluminum extrusion profiles are highly versatile and can be used in a wide range of applications, including:

Architectural designs: Perfect for framing, curtain walls, and other structural elements in modern buildings.

Custom fittings: Ideal for creating custom components for machinery, furniture, and other industrial applications.

Retail displays: The sleek matte black finish makes it a great option for high-end retail environments, adding a touch of elegance to product displays.

Lighting solutions: Its durability and aesthetic appeal make it suitable for LED lighting fixtures and other lighting systems that require both functionality and style.

Factory Strength and Certifications

Our factory is equipped with state-of-the-art technology and a dedicated team of professionals, ensuring that we consistently produce high-quality matte black coated anodized aluminium extrusions. We are committed to meeting the needs of our clients and providing tailored solutions that meet the specific demands of each project.

ISO 9001 Certified: Our manufacturing processes are certified to meet the highest international standards for quality management, ensuring consistency and reliability in every product.

ROHS Compliant: Our products comply with environmental standards, ensuring that they are safe for both people and the environment.

Custom Solutions: We offer a range of customization options for sizes, finishes, and specifications, allowing us to cater to specific project requirements.

FAQ

What is anodized aluminum?

Anodized aluminum is aluminum that has undergone an electrochemical process to form a protective oxide layer on its surface. This process increases the material’s resistance to corrosion, wear, and environmental damage.

How can the matte black aluminum extrusion be used?

This extrusion is perfect for use in architectural applications, custom fittings, and structural frameworks. It can also be used for retail displays, signage, and even lighting systems.

Is the anodized aluminum profile black extrusion customizable?

Yes, we offer customization for sizes, shapes, and finishes. If you need a specific configuration for your project, feel free to reach out to us, and we will provide tailored solutions to meet your needs.

How do I maintain the coated aluminum extrusion profiles?

Maintaining this product is simple. Regular cleaning with a soft cloth and mild detergent is sufficient to keep the surface looking pristine. Avoid using abrasive materials that could scratch the anodized finish.

What is the difference between anodized aluminum and regular aluminum?

Anodized aluminum has a thicker oxide layer, providing increased corrosion resistance, a more durable surface, and enhanced aesthetic appeal. Regular aluminum, on the other hand, lacks this protective layer and is more susceptible to environmental damage.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on