Material & Temper :

Aluminium Alloy 6063 T6Length :

3.8 metersApplication :

Bottom cover of electric vehicle battery packLead time :

10 to 30 daysExecutable Quality Standard :

According to customer agreement standardsSurface Treatment :

Mill FinishPackaging method :

According to customer agreement standardsCross Section Size :

Width:555 millimeters; Wall Thickness:2.0 millimetersSuqian Sunmay Aluminium Company Limited, a renowned specialist in the aluminum profiles industry, excels in crafting premium-quality aluminum alloys across an extensive range, including 5052, 6063, 6061, 6060, 6082, 6005, 6201, 6463, 7001, and 7075, with tempering options of T4, T5, and T6 to suit diverse applications. Equipped with cutting-edge technology, our forward extrusion presses feature a maximum sectional diameter capacity of 700mm and the capability to produce ultra-thin walls with precision down to 0.25mm. Additionally, our reverse extrusion machines and drawing facilities empower us to fabricate seamless and high-precision aluminum tubes.

Dedicated to surface excellence, we provide a comprehensive array of treatments, such as anodizing (with both coloring and dyeing capabilities), powder coating, wood grain transfer, polishing, and brushing, all of which enhance the aesthetic appeal and durability of our products. With vast experience in adhering to standards like GB5237, TS16949, EN12020, EN755, and EN573, we ensure compliance with international benchmarks.

Our diverse portfolio caters to various sectors, encompassing architectural aluminum profiles, industrial aluminum solutions, and automotive aluminum components. With a global reach spanning over 50 countries, our architectural aluminum profiles have garnered significant international acclaim, particularly lauded by distributors in more than 20 nations.

Grounded in the values of "Customer-Centered, Commitment Fulfilled," we are relentless in our dedication to exceeding customer expectations. Visionary in our endeavors, we aspire to achieve "Leading Cost-Effectiveness in China's Aluminium Industry," continually innovating and optimizing to deliver unparalleled value to our clients worldwide.

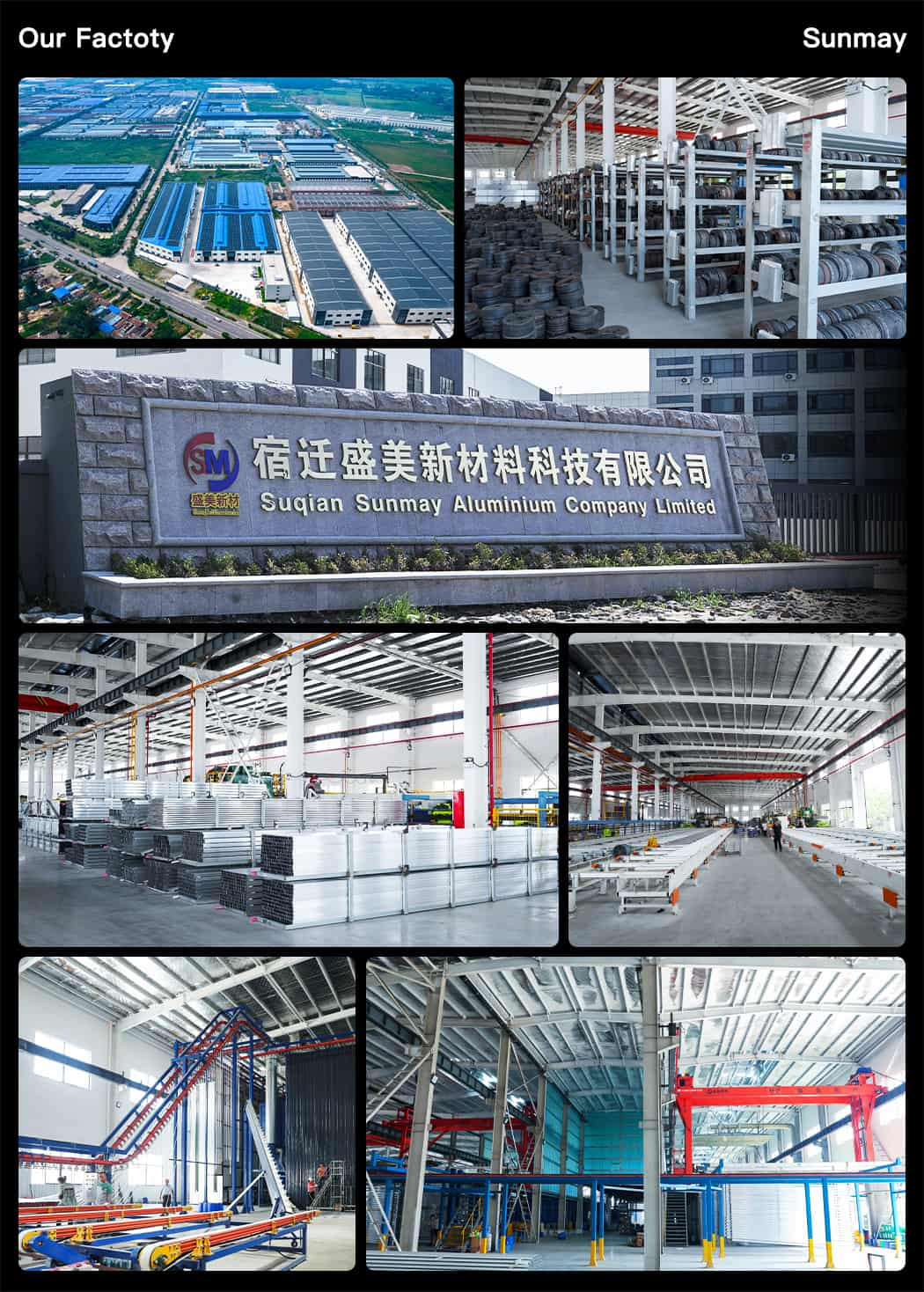

FACTORY VIEW

Are you tired of bulky, heavy battery packs in electric vehicles? Meet the game-changer in EV technology: our ultra-thin, yet incredibly durable, aluminum extrusion for battery pack base protection! At merely 2.0mm in wall thickness, this型材 boasts a larger cross-sectional size while maintaining unparalleled strength and reliability.

Picture this: an aluminum miracle that's lightweight as a feather but tough as nails. It's the secret weapon that keeps your EV's heart - the battery pack - safeguarded against the perils of the road, without adding unnecessary heft. This innovation isn't just about slimming down; it's about maximizing space, efficiency, and range in the ever-competitive world of electric vehicles.

But why stop at thinness? Our aluminum extrusion is a testament to engineering brilliance, offering exceptional thermal conductivity to dissipate heat and ensure optimal performance. It's watertight, crash-resistant, and built to withstand the test of time. Plus, its sleek design seamlessly integrates into any EV model, ensuring your vehicle isn't just high-performing but also aesthetically stunning.

In an era where sustainability meets cutting-edge technology, our aluminum extrusion sets the benchmark for innovation. It's not just an upgrade; it's a revolution in how we think about EV battery protection. So, why settle for less when you can have the best? Elevate your electric vehicle experience with the future of battery pack protection – because thin doesn't mean weak; it means revolutionary.

Lead time: 10 to 30 days.

Executable Quality Standard: GB5237 Or per customer-specified quality standards.

Moq: 1 ton for each order

OEM&ODM: Acceptable

Email: sales@sunmayalu.com

Mob/Whatsapp/Wechat: 17366266559

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on