As an advanced manufacturing technology, aluminum CNC machining is gradually changing the face of the manufacturing industry, improving product quality and production efficiency, and bringing innovation opportunities and development space to enterprises. In the future, with the advancement of technology and the expansion of application scope, aluminum CNC machining will show its unique charm and value in more fields and promote the continuous progress of the manufacturing industry.

Material & Temper :

Custom Aluminum Alloy with Tempering ProcessLength :

By Custom LengthApplication :

Automotive, Electronics Industry, Construction IndustryLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Anodizing/Powder Coating/Brushing/PaintingColor :

Silver, Champagne, Brown, Bronze, Black, GoldenPackaging method :

Customized according to customer requirementsIn today's rapid development of manufacturing, aluminum CNC machining has become an indispensable technology to meet the market demand for high-precision products, improve production efficiency and product quality, and give enterprises a competitive advantage. Its application range ranges from aerospace to automobile manufacturing to electronic products, and is everywhere:

Choosing high-quality service providers to cooperate can ensure professional technical support and services during the project cycle, and jointly develop innovative products. For example, an automobile manufacturer cooperated with an aluminum CNC machining company to develop new engine parts, using the latest CNC technology and high-performance aluminum alloy materials to reduce weight by 30%, increase strength by 20%, and significantly improve engine performance and fuel economy.

Suqian Sunmay Aluminium Company Limited, a renowned specialist in the aluminum CNC machining industry, excels in crafting premium-quality aluminum alloys across an extensive range, including 5052, 6063, 6061, 6060, 6082, 6005, 6201, 6463, 7001, and 7075, with tempering options of T4, T5, and T6 to suit diverse applications.

Dedicated to surface excellence, we provide a comprehensive array of treatments, such as anodizing (with both coloring and dyeing capabilities), powder coating, wood grain transfer, polishing, and brushing, all of which enhance the aesthetic appeal and durability of aluminum CNC machining. With vast experience in adhering to standards like GB5237, TS16949, EN12020, EN755, and EN573, we ensure compliance with international benchmarks.

Our aluminum CNC machining caters to various sectors, encompassing architectural aluminum profiles, industrial aluminum solutions, and automotive aluminum components. With a global reach spanning over 50 countries, our architectural aluminum profiles have garnered significant international acclaim, particularly lauded by distributors in more than 20 nations.

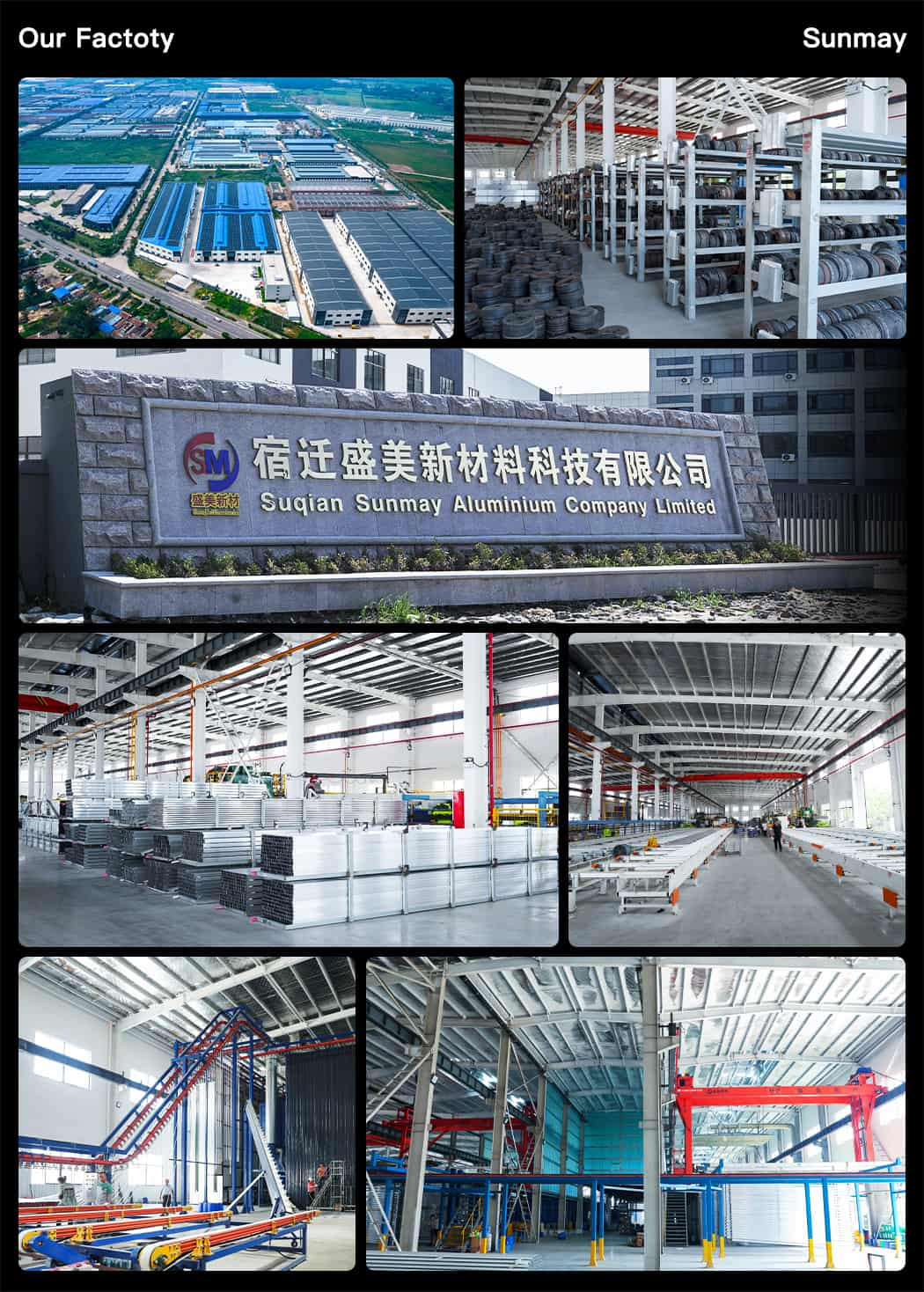

FACTORY VIEW

Lead time: 10 to 30 days.

Executable Quality Standard: GB5237 Or per customer-specified quality standards.

Moq: 1 ton for each order

OEM&ODM: Acceptable

Email: sales@sunmayalu.com

Mob/Whatsapp/Wechat: 17366266559

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on