Material & Temper :

Custom Aluminum Alloy with Tempering ProcessLength :

By Custom LengthApplication :

Automotive, Electronics Industry, Construction IndustryLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Anodizing/Powder Coating/Brushing/PaintingColor :

Silver, Champagne, Brown, Bronze, Black, GoldenPackaging method :

Customized according to customer requirementsSuqian Sunmay Aluminium Company Limited, a renowned specialist in the aluminum profiles industry, excels in crafting premium-quality aluminum alloys across an extensive range, including 5052, 6063, 6061, 6060, 6082, 6005, 6201, 6463, 7001, and 7075, with tempering options of T4, T5, and T6 to suit diverse applications. Equipped with cutting-edge technology, our forward extrusion presses feature a maximum sectional diameter capacity of 700mm and the capability to produce ultra-thin walls with precision down to 0.25mm. Additionally, our reverse extrusion machines and drawing facilities empower us to fabricate seamless and high-precision aluminum tubes.

Dedicated to surface excellence, we provide a comprehensive array of treatments, such as anodizing (with both coloring and dyeing capabilities), powder coating, wood grain transfer, polishing, and brushing, all of which enhance the aesthetic appeal and durability of our products. With vast experience in adhering to standards like GB5237, TS16949, EN12020, EN755, and EN573, we ensure compliance with international benchmarks.

Our diverse portfolio caters to various sectors, encompassing architectural aluminum profiles, industrial aluminum solutions, and automotive aluminum components. With a global reach spanning over 50 countries, our architectural aluminum profiles have garnered significant international acclaim, particularly lauded by distributors in more than 20 nations.

Grounded in the values of "Customer-Centered, Commitment Fulfilled," we are relentless in our dedication to exceeding customer expectations. Visionary in our endeavors, we aspire to achieve "Leading Cost-Effectiveness in China's Aluminium Industry," continually innovating and optimizing to deliver unparalleled value to our clients worldwide.

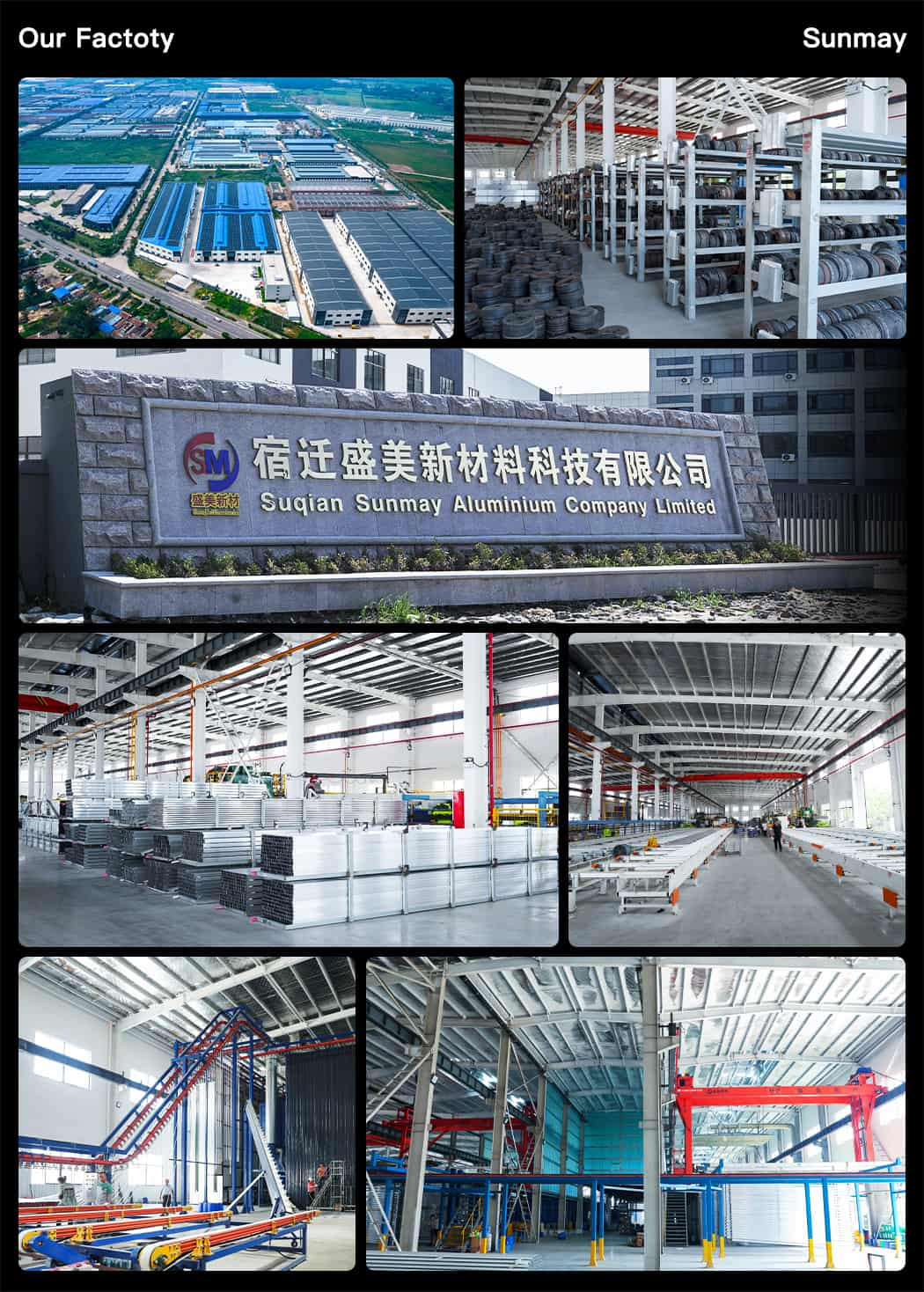

FACTORY VIEW

In today’s manufacturing landscape, the demand for precision-engineered components is growing, with aluminum being a standout material due to its lightweight and durability. CNC aluminum machining has become essential for industries like automotive, aerospace, and electronics, allowing for intricate designs and high accuracy.

CNC machining optimizes cutting paths, reducing waste compared to traditional methods and ensuring consistent quality through automation. A key element of this process is tempering, which involves heat treatment to enhance aluminum’s strength and hardness. This process is crucial for producing components that can withstand significant stress, particularly in automotive applications.

China has emerged as a global manufacturing hub, excelling in aluminum profile production thanks to its advanced technology and skilled workforce. Chinese manufacturers effectively scale production while maintaining quality, using state-of-the-art CNC technologies to create custom profiles tailored to specific needs. This capability makes sourcing aluminum machining parts from China both cost-effective and reliable.

As industries evolve, the need for innovative materials and manufacturing techniques will continue to rise. CNC aluminum machining parts are pivotal in addressing complex engineering challenges, and advancements like artificial intelligence are set to enhance precision and efficiency. The focus on sustainability will also drive the adoption of eco-friendly practices, further aligning the aluminum industry with consumer expectations.

Overall, CNC aluminum machining parts play a vital role in modern manufacturing, offering versatility and performance that meet the demands of various applications.

Lead time: 10 to 30 days.

Executable Quality Standard: GB5237 Or per customer-specified quality standards.

Moq: 1 ton for each order

OEM&ODM: Acceptable

Email: sales@sunmayalu.com

Mob/Whatsapp/Wechat: 17366266559

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on