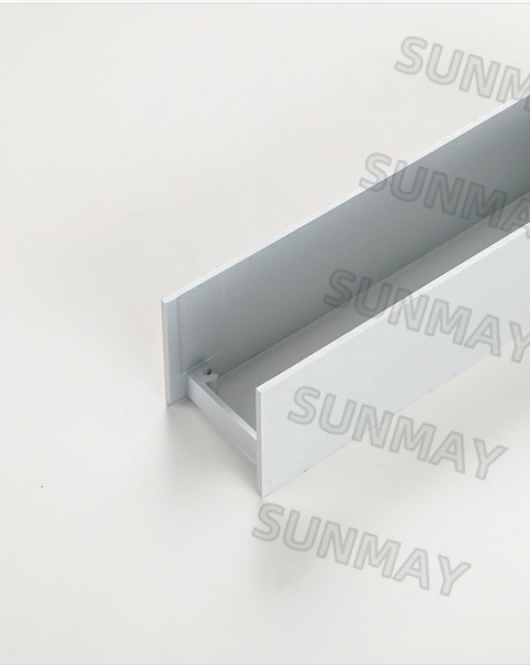

Our Precision CNC Machining Aluminum Parts are manufactured with high accuracy and strict quality control, ensuring durability and superior performance for various industrial applications.

Material & Temper :

Custom Aluminum Alloy with Tempering ProcessLength :

By Custom LengthApplication :

Automotive, Electronics Industry, Construction IndustryLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Anodizing/Powder Coating/Brushing/PaintingColor :

Silver, Champagne, Brown, Bronze, Black, GoldenPackaging method :

Customized according to customer requirementsWe specialize in OEM CNC Machined Aluminum Parts that cater to diverse industrial applications. Whether you need prototypes or mass production, we offer customized solutions with tight tolerances and excellent surface finishes.

Material Options: 6061, 6063, 7075, and other aluminum alloys

Processing Tolerance: ±0.01mm (customizable based on project requirements)

Surface Treatment: Anodizing, sandblasting, powder coating, polishing

Machining Methods: CNC milling, CNC turning, drilling, tapping, and more

Custom Designs: We produce Custom Aluminum Components Manufacturer designs based on 2D/3D CAD drawings

Our High-Quality CNC Aluminum Parts are ideal for industries requiring precision engineering and exceptional material properties.

High Precision & Tight Tolerances – Our Precision CNC Machining Aluminum Parts are manufactured with state-of-the-art machinery, ensuring minimal deviation and superior accuracy.

Durability & Strength – Using premium-grade aluminum alloys, our parts offer excellent mechanical properties, including corrosion resistance and lightweight strength.

Custom Manufacturing – As a Custom Aluminum Components Manufacturer, we provide tailored solutions based on your specifications.

Smooth Surface Finish – With advanced finishing techniques, we guarantee aesthetically pleasing and functional High-Quality CNC Aluminum Parts.

Fast Production & On-Time Delivery – We optimize machining processes for high efficiency, reducing lead times and ensuring timely delivery.

Aerospace & Automotive: Structural and precision parts for enhanced performance

Electronics & Telecommunications: Heat sinks, enclosures, and connectors

Medical & Healthcare Equipment: Surgical instruments, medical devices

Industrial Machinery: Custom machine components for automation systems

Robotics & Automation: Lightweight yet strong parts for robotic mechanisms

As an experienced Custom Aluminum Components Manufacturer, our factory is equipped with cutting-edge CNC machining centers and a professional engineering team dedicated to quality and efficiency.

Production Capacity: Over 10,000 precision parts produced per month

Advanced Equipment: 3-axis, 4-axis, and 5-axis CNC machines for complex designs

Skilled Engineers: Over 15 years of expertise in OEM CNC Machined Aluminum Parts

Strict Quality Control: Every part undergoes rigorous inspection before shipment

Global Export Experience: Supplying to North America, Europe, and Southeast Asia

To ensure the reliability and compliance of our High-Quality CNC Aluminum Parts, we strictly adhere to international standards and certifications:

ISO 9001 Certification – Quality management system ensuring consistent performance

RoHS Compliance – Environmentally friendly and lead-free aluminum machining

CE Certification – Meeting European safety and quality standards

Material Reports & Inspection Reports Available – Providing full transparency on product specifications

Q1: What is the minimum order quantity (MOQ) for CNC aluminum parts?

Our MOQ varies based on part complexity, but we accept low-volume and prototype orders.

Q2: Can you work with custom drawings and designs?

Yes, we specialize in Custom Aluminum Components Manufacturer solutions based on 2D and 3D CAD files.

Q3: How long is the production and delivery time?

Standard orders take 7-20 days. Custom and bulk orders may require additional time.

Q4: What surface finishes do you offer?

We provide anodizing, sandblasting, powder coating, and other surface treatments for High-Quality CNC Aluminum Parts.

Q5: How do you ensure the quality of CNC-machined aluminum parts?

We conduct 100% quality inspection, including dimensional checks and material testing, before shipment.

Tags :

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on