The advantages of customized CNC aluminum parts are significant: high flexibility and strong customization capabilities, which can meet complex geometric shapes, special sizes and surface treatment requirements; using advanced CNC technology, the error is extremely small, ensuring high precision and high quality; effectively shortening the product development cycle , accelerate time to market, and adapt to the rapidly changing market.

Material & Temper :

Custom Aluminum Alloy with Tempering ProcessLength :

By Custom LengthApplication :

Automotive, Electronics Industry, Construction IndustryLead time :

10 to 30 daysExecutable Quality Standard :

GB5237, TS16949, EN12020, EN755, EN573, Or according to customer agreement standardsSurface Treatment :

Anodizing/Powder Coating/Brushing/PaintingColor :

Silver, Champagne, Brown, Bronze, Black, GoldenPackaging method :

Customized according to customer requirementsIn today's highly competitive manufacturing industry, customized production has become the key for companies to stand out. "Customized CNC aluminum parts" frequently appear in the field of precision machinery and high-end equipment manufacturing, symbolizing efficient and high-precision production capabilities and meeting the personalized needs of customers. ability.

Customized CNC aluminum parts are parts obtained by precisely cutting, shaping, and polishing aluminum materials using computer numerical control technology according to the specific needs of customers. It is different from traditional mass production in that it emphasizes personalized design and small batch or even single-piece production, and can flexibly cope with complex shapes and special specifications.

Customized CNC aluminum parts are widely used in aerospace, automotive, medical equipment, robotics, and high-end consumer goods. The aerospace industry requires customized parts with strict design specifications to ensure flight safety; the automotive industry pursues lightweight and personalized design, and customized CNC aluminum parts are just what they need. Medical devices and high-end consumer products have extremely high requirements on precision and quality of parts.

When implementing a customized CNC aluminum parts project, you need to pay attention to: select appropriate aluminum alloy materials according to the application environment and performance requirements; work closely with suppliers to obtain high-quality products and professional technical support; balance budget and efficiency to ensure project feasibility and economy .

With technological advancement and market diversification, customized CNC aluminum parts will play a role in more fields. Enterprises and individual users should value its value and actively seek development opportunities. Understanding and applying customized CNC aluminum parts technology to drive business forward is the key to coping with market competition.

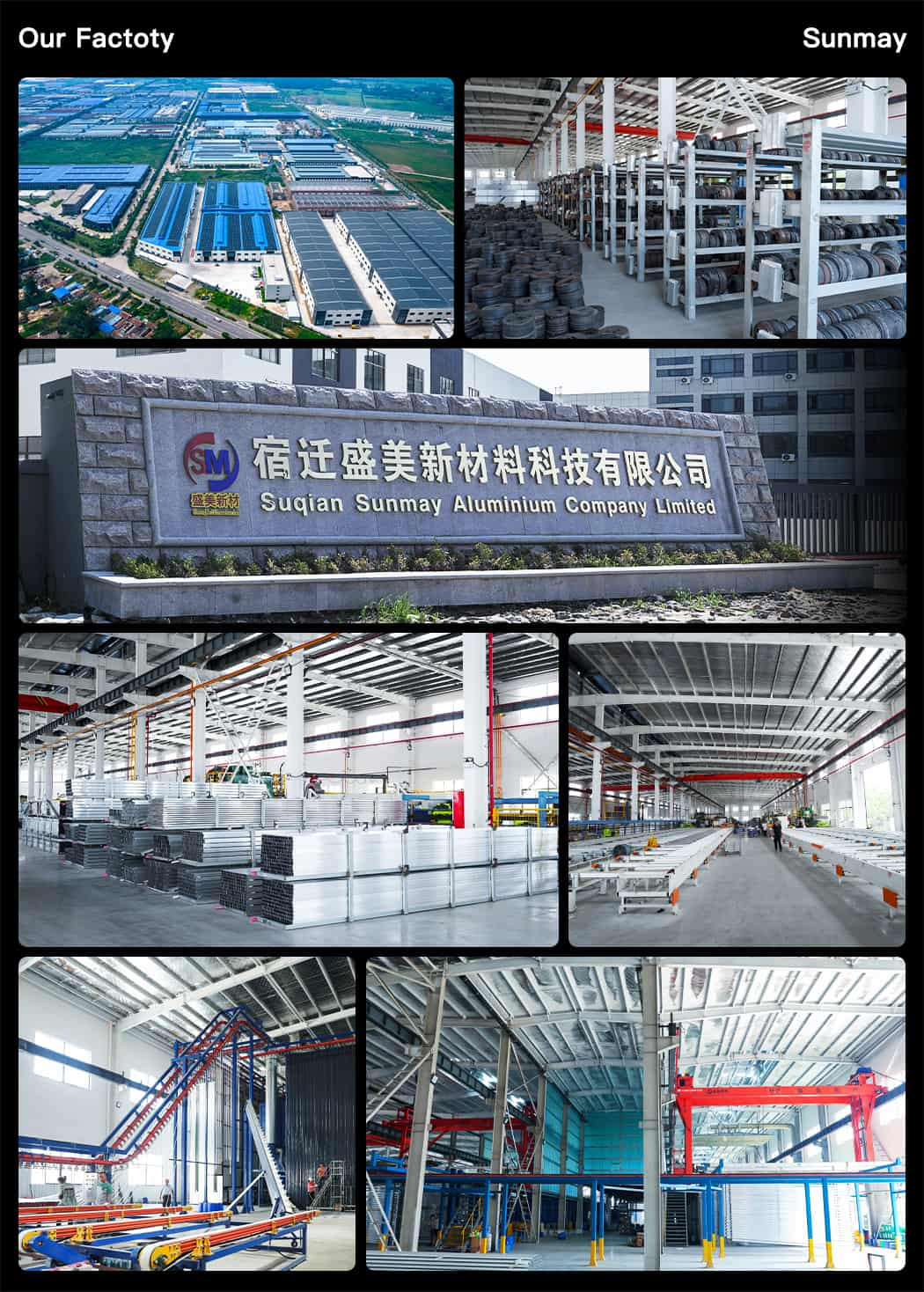

FACTORY VIEW

Lead time: 10 to 30 days.

Executable Quality Standard: GB5237 Or per customer-specified quality standards.

Moq: 1 ton for each order

OEM&ODM: Acceptable

Email: sales@sunmayalu.com

Mob/Whatsapp/Wechat: 17366266559

Whatsapp : +8617366266559

Email : sales@sunmayalu.com

Tel : +86 -17366266559

Hi! Click one of our members below to chat on